-

Constructions devices are expensive. For this reason you should research the market with the greatest possible care prior to buying self loading concrete mixers as well as other such devices. Generally, thorough research pays off adequately, since it is the best method to locate excellent deals on top quality equipment and machines. Many business owners buy their equipment from China manufacturers. Here are a few explanations why they actually do it and why you need to consider doing the work, too.

Affordable prices are the initial and foremost benefit of buying industrial machines and devices from China. You can get your self loading mixer without worrying you're planning to need financing to start your company. China manufacturers have the ability to offer less expensive costs on their customers mainly because they have lower production costs and overhead expenses. Because of this they could market their items at inexpensive price points but still come up with a profit during this process. However, this may not be the sole advantage you get if you get your equipment with this country. There are lots of other top reasons to overlook the local suppliers in support of overseas ones.

One more reason good reasons to get a China self loading concrete mixer is you can easily compare lots of options. All you need is to utilize a worldwide trading directory including AliBaba or AliExpress. These web portals list 1000s of China businesses ready to reach out to international customers. Every one of these companies maintain professional business pages on these directories. They normally use this chance to showcase their best equipment and machines, to showcase photos in their factories, as well as explain prospective clients the advantage of buying their products. When you know which kind of self loading concrete mixer you want, you'll surely find several viable choices on AliBaba. All you should do is to carry out a careful screening of all sellers, and discover probably the most reliable ones. In most cases, the higher the rating and the number of positive comments and reviews, the higher the chances how the seller is worth trust.

Communication by using these China business owners is pretty simple and easy , straightforward. You should use the contact information on the business pages to reach out to these with queries about their products and services. This may show to be useful particularly when you want a less widespread type of self loading concrete mixer. You'll be capable of ask for detailed technical sheets and for any other little information you may have to make a purchase. Besides, shopping on these business directories allows you to utilise the escrow payment system that provides you the peace of mind that you'll receive just what you've purchased. Escrow can be a system which utilizes a 3rd party back account to withhold your money till you confirm that you've received your order.

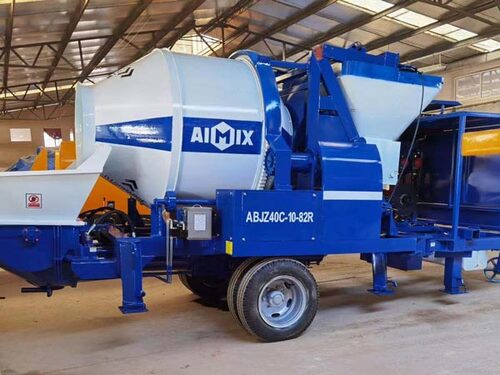

These are a couple of explanations why there is no doubt that your self loading concrete mixer will probably be as effective as this kind of devices you could potentially possible find on your local market. Get one in AIMIX.

your comment

your comment

-

Operating a mixing plant might be exciting, but for a number of people they actually do not realize their are different kinds of plants. This is where people should know about the three main classes that happen to be present with a bitumen mixing plant. By understanding this, it is going to make it simpler for people to determine if the plant is just one they may enjoy working at and even one that will require considerably more in the way of maintenance than what people think these are going to need to look after.

Batch heater kinds of plants are just what the name makes it appear to be it can be. This really is a plant which has a heater that is going to take the materials from multiple resources and heat them up to and including set temperature. While this will be using the heated materials they have and putting them out in to the mixers that may add the aggregates along with other materials that are going to be employed to complete the asphalt. However, this kind of plant is often the required starting point for you to make the asphalt.

Semi-continuous is the type of plant that will be used for mixing the type of material on a basis that will have some intermission inside them. This way the materials will probably be mixed together, but they may not be mixed up completely for the final product. So this is a way that will help people in getting to have the materials partially mixed and possess them finished mixing at the job site. So men and women will enjoy the point that this is a mixing process that is going to make it easier to enable them to complete the position. Learn more here.

Continuous mixing plants are another kind of plant and one of the most common ones that people are utilized to seeing. With this type of plant, it really is totally different compared to the batch plants since this is a plant that might be making the asphalt in a fashion that it will probably constantly be producing asphalt. These plants are the common ones that men and women are utilized to seeing and frequently the type of plant that individuals should have should they be planning on making roads or other items which will require asphalt with an almost constant basis.

Having the capability to understand about the three main classes of bitumen plant for sale is a good thing. However, what folks have to realize is this can be a lot harder to examine than they might think. By getting a broad idea about the three forms of plants, though, it will probably be rather simple for people to discover the right plant and know that it must be gonna meet the requirements. Without it information, people may struggle to get the right plant setup or perhaps order their next batch of asphalt from your right form of company.

your comment

your comment

-

If you have readily available several self loading concrete mixers, you understand how efficient your small business can run. You possibly will not realize how helpful these units are till you have a few of them which can be assisting you complete jobs in advance. Not all are made the exact same size. A few will be smaller or larger, which is dependent upon the business that you will be purchasing them from. They could have a plethora of the latest models of, but provided you can select one on sale from one of those businesses, you may consider buying one. You can find different capacities of self loading concrete mixers that you have to consider prior to deciding to buy your first, or another, one of these brilliant to your business.

Precisely Why Are These So Helpful For A Concrete Company?

These are generally exceptionally helpful for three specific reasons. Firstly, they can be self loading. You no longer have to worry about mixing the many various aspects of the concrete that you are intending to mix because it will likely be preprogrammed into the system. Second, there is no must mix within the concrete at the main batching plant then deliver it using a standard concrete mixer. Just mix what you need at the locations where the tasks are and this will save you time and expense. Finally, they are one of the most efficient concrete mixers in the industry, not only for gas mileage, nevertheless in how fast they can mix the concrete. Every one of these different aspects prompt a lot of people to think about changing up to these rather than standard concrete mixers.

Do You Know The Different Capacities Of Such Concrete Mixers?

The various capacities that you might want to check out will include exactly how much concrete might be mixed up at the same time, and what the discharge capacity is. The normal drum capacity for one of these simple units is going to be over 3000 leaders. When it comes to the discharge capacity, this is approximately the same, usually a bit less. If you can locate one which includes these parameters, in addition to an exceptional drum mixing speed, you will understand that you have found the right one. Choose one here.

Where You Can Get One Which Is Priced Affordably

Your quest for the best prices will often cause you to countries including South Africa, the Philippines or China. If you happen to remain in those countries, you can usually benefit from the reduced price of these products. Even when you are not during these countries, combined with expense of shipping, you undoubtedly can't get a better price. Many people will obtain them from businesses during these countries due to their quality and how much they may cost.

Transitioning from standard concrete mixers to such self loading mixers may be a costly process. They will certainly cost more than regular mixers, however they are a lot more versatile. They permit you to bring all your components together with you, mix up the concrete rapidly, and poor that concrete so you can move on to the following job. This can save you time, and a considerable amount of money, after you pick a self loading concrete mixer Kenya that has the correct capacities.

your comment

your comment

-

If you have lots of fly ash for sale in your vicinity, you can put in place the business of making and selling fly ash bricks. These bricks are in huge demand since these are eco friendly and utilize fly ash that will otherwise go waste and make pollution. Various kinds machines are you can find today to make these bricks however it is important that you can invest in a machine that is certainly specifically made for making fly ash bricks. Here is a set of several of the key components of this machine.

The procedure commences with a mixer. In this mixer, various raw materials such as cement, fly ash, sand and water are mixed from the desired proportion. Design of the mixer is very important as without proper design, the mixing won't be homogeneous which will create problems. It must also be produced of thick material to ensure that it keeps operating without any issues for several years. This mixer is run by an electric motor which is accompanied by a gearbox to gear box to make sure homogeneous mixing. In terms of the capacity in the mixer is concerned, it depends on the development capacity in the fly ash brick machine. With regards to discharge from your mixer, it is possible to opt for a manual discharge option or perhaps a completely automatic one, depending on your budget and the setup.

Another portion of the method is the belt conveyor that is utilized for transporting materials from your mixer on the press. There are a lot of rollers inside the conveyor belt and those need to be made from top quality materials. The most significant thing about this whole setup is definitely the hydraulic bricks press. Of course, it needs to be produced from the highest quality materials. This machine functions by applying very high pressure starting from 6 to 8 metric tons on each brick. In the case of automatic machines, this portion of the process is handled automatically by using a pc controlled system. View more here.

Probably the most important areas of the full setup is definitely the PLC or programmable logic controller. This is basically the heart of the setup and it may be programmed to operate in various modes including fully automatic, semiautomatic and also manual mode. Since PLC controls the full setup, it is vital that it is made from the best quality components.

With regards to the ability is concerned, you can get this auto bricks machine in various capacities starting from as few as 1000 bricks hourly to more than 4000 bricks hourly though you can buy higher capacity machines. The capability needs to be decided based on the interest in these bricks within your location. Do not buy an excessive amount of capacity as it can provide inefficiency at the same time if you are incapable of find buyers for your bricks. Therefore, select the capacity carefully after conducting market research within your location to figure out the requirement for these bricks.

Overall, the fly ash bricks happen to be in huge demand everywhere. They are resilient and strong, and the raw material necessary for making these bricks is definitely available near coal-based power plants. So, in case you have a coal-based power plant with your vicinity or fly ash is readily available, you should seriously think about establishing a fly ash brick making plant and turn into your own boss.

your comment

your comment

-

Bitumen, a mixture made out of natural hydrocarbons, is normally useful for road surfacing as well as for roofing. However, before this substance works extremely well, it must be mixed with a bitumen mixing plant. To keep a plant such as this working efficiently, it's important to get the best equipment.

Finding Equipment That Meets Your Requirements

The machinery you buy is definitely the most essential element of your hot mix asphalt plant. As a result, you'll want to make sure that the device you get is well fitted to your requirements. It's smart to set a financial budget before starting shopping. That way, you'll be capable of focus your attention on options that happen to be comfortably in your budget range.

It's equally important to consider your needs when choosing equipment. What are your day-to-day production needs? Are you searching for portable machinery, or searching for something larger and stationary? If you know what exactly you're searching for, it will likely be simple for you to narrow down your alternatives and discover something that is useful for you.

When looking for your choices, it's smart to consider the brands behind the machinery. If you opt for equipment which is made by a well-known, respected brand, you can expect that the machinery holds up more than time.

Selecting The Best Vendor

It's essential to get the right equipment, but it's also wise to buy that machinery from the right source. Due to this, you ought to carefully look at the vendors that provide this type of machinery. Regardless of who you opt to work with, you should ensure that this vendor has fair prices, a robust selection, as well as a positive reputation.

Some vendors may have low prices, but the cost of shipping could find yourself increasing what you pay. Other vendors may take too much time to ship out equipment, which could cause problems for you. Make sure you're conscious of the pros and cons of dealing with various vendors. If you make an informed decision, you'll have fewer regrets in the long run. Learn more info here.

Maintaining Your Equipment

Once you've purchased the machinery you need, you'll must try to ensure that is stays in good working order. To be able to take care of your equipment, you'll have to clean it regularly and thoroughly. It's feasible for debris to accumulate within a bitumen mixing machine if it is not properly cleaned.

Along with cleaning, lubrication is vital. These appliances have small moving parts, which parts can produce friction should they be improperly lubricated. This can cause parts to put on down, which suggests they may eventually should be replaced. Check the manual that came with your equipment to help you see what sort of lubricant you ought to be using. It's also smart to visually inspect your machinery to help you spot potential issues.

A bitumen mixing plant can be a valuable investment. Because it has multiple applications, a plant like this could be extremely profitable. Follow the advice above, and you'll be able to be sure that your plant runs very smoothly.

your comment

your comment

-

Concrete pumps may represent one of the more important industrial items that you may have at the workplace. You might be pouring concrete for foundations each and every day, or using it for other reasons. If you have multiple concrete mixers, along with your pump quickly scans the blogosphere, you generally require a backup. In case you are in Malaysia, chances are there are affordable places that you can get concrete pumps anytime to, whether locally produced, or from the different country that is going to offer you a much lower price. For the greatest concrete pump in Malaysia, this is the way you can purchase one today

Where Would You Like To Find These In Malaysia?

You can find these concrete pumps in various locations during Malaysia. It is actually a quite popular item. They may be small enough, and diverse enough, to be bought from mass quantities. They can be produced in mass quantities for a discounted price. It is advisable to search for the firms that are producing a substantial number of them and learn simply how much they may be charging. This will either be displayed in advertisements that they are using to promote them, or contact companies directly to acquire a quote from them. View more here.

Price Versus Quality

The retail price which you pay may also be reflective of the caliber of the machine which you purchase. However, that may not be the case. Occasionally, you are likely to pay money for one of those that will be in a extremely low price, yet it will probably be among the finest ones that have been ever made. To find these, you should first research and determine what companies are making the best ones and after that choose which one to acquire. So long as it can be coming from one of these simple companies that is well known for producing portable concrete pumps which can be exceptional, you will be aware that the price is not reflective at all of how efficient this concrete pump will likely be.

The Way To Get Them Delivered Quickly

Getting these delivered quickly is only a few finding a distribution site, or perhaps a manufacturer, that happens to be near to where you are in Malaysia. It may take several hours to undergo the many listings, contact the firms, nevertheless, you may ultimately find this business. Once you have placed your order, within the duration of a couple of days, it will be brought right to your place of business. Providing you have verified that this works specifically together with the concrete mixers that you may have available, it is possible to attach it and start using it to begin doing more jobs using this efficient and well designed concrete pump.

There are many places to obtain a concrete mixer pump in Malaysia provided that you carry out the research and find these businesses. Whether it is domestically made, or should it be being introduced from a major international company, they will always be available. If you need the most effective prices on the top-of-the-line models, this can take a few hours of research from you. Once you have completed your quest, you will understand once it arrives, it will most likely be an exceptional concrete pump which can be used to assist your business be a little more efficient.

your comment

your comment

-

A diesel concrete mixer is a very common apparatus found on most construction job sites around the world. Powered by way of a diesel motor, and ultizing hydraulics, they are able to produce and pour concrete very rapidly. How big the drum which is used, and exactly how that it must be constructed, will give rise to if you wish to own one of these brilliant units. You must also think about the very specific parameters connected with each concrete mixer that may be manufactured. The simplest way to have the exact one you want is for starters considering their specifications.

How Do These Concrete Mixers Work?

To start with, there are several styles which are made today. Many of them may have a few interior blades that may churn the concrete continually. They may push the concrete forward, and based on the potency of the diesel motor that is used, it might emerge quite rapidly. The reason being the pump will also make use of the power given by the diesel motor which is component of each unit. Several of the specifications to think about include the discharging capacity, the dimensions of the container, and the charging capacity of each and every system.

Do You Need A Stationary Or Portable Unit?

You will find advantages and drawbacks to every one of these systems. The stationary unit can produce more concrete yet you are limited by how many concrete mixing trucks available for you. On the flip side, portable units are much more convenient to make use of, particularly when by using a self-loading concrete mixer. The primary drawback is the volume of concrete that can be generated by these smaller portable systems. You could possibly get a bigger stationary concrete production plant, in addition to several concrete mixing trucks, that will allow your organization to expand.

Different Physical Aspects Of These Mixers

There are several different components that define these machines. This consists of the mixing drum, friction wheel, the hydraulic motor, the diesel or electric motor, and also the pump. When you assess each one of these, you may determine that you are currently keen on pumping the concrete fast instead of mixing it rapidly. It just is dependent upon how productive you wish to be, and just how much you need to dedicate to one of these simple concrete mixer production plants. One other physical aspect to take into account is when easy they are to create. Most of these can be achieved very rapidly. If you deal with a company that is famous, you won't need to bother about the different components not being shipped which may prevent you from applying this once it arrives in the future.

Diesel concrete mixers are among the most in-demand types which are sold. So long as you get access to enough diesel fuel, these can run indefinitely. This business that you obtain these from needs to have a track record for producing exceptional equipment. They can offer good prices, effectively saving your business 1000s of dollars whenever you make this particular investment. By requesting multiple quotes on diesel concrete mixers which you find online, you can expect to eventually have more than one of those units delivered so that you can produce more concrete.

your comment

your comment

-

It is very important to possess a concrete pump that may serve your preferences. If you have a business that is pouring concrete daily, you want a reliable concrete pump producing the thing you need. This might be a big or small unit. It might be a transportable one you could take to remote locations on the back of your truck. Most of them that are made come with a boom which is an apparatus that permits you to pour the concrete into specific locations. This enables you to maintain the concrete pump stationary, delivering the concrete through this final, which makes it much better to complete the work you are doing.

How To Find Affordable Ones

You will discover a lot of companies that produce boom concrete pump for sale. Many of these businesses also produce asphalt and cement mixers also. The greater diverse the corporation is, the larger the probability that they will have multiple concrete pumps for you to choose between. Countries in Asia most often have the highest quality, along with the lowest prices that there are actually worldwide. They generally advertise online, specifically using websites in which there advertising can make it to the the majority of people internationally. These others that may likely have the least expensive prices, but you still must compare the ones that each company is selling.

Ideal Way To Select The Right Boom Concrete Pump

One of several most effective to select the correct one would be to compare the specs or details. Every one will be shown different specifications. The max concrete pumping pressure, as well as the max theoretical concrete output, or two of the most basic facts to consider. The concrete cylinder diameter, max aggregate diameter, along with the horizontal and vertical distance for delivery should also be area of the decision-making process. When you have evaluated them all, and checked how much they are selling them for, you can place your order 100 % confidence. Learn more here.

Is This The Easiest Way To Buy Something?

In many instances, online shopping is going to present you the best bargain. You will likely have some that will be obtainable in your local area. You can compare the values, but it is likely that you will get the more effective deal from a company that can offer to sell a brand-new unit for a lesser price.

The concrete boom pump that you end up purchasing needs to be one which you can use to generate enough concrete for every job. Whether you receive a power concrete mixer, or one of several other units that makes ready mix, it will have got a boom that will help you complete your jobs considerably more quickly. Shipping time is typically a couple weeks, but it may be a little longer, based upon your house worldwide. How much cash that you just helps save can certainly make your unwanted weight worthwhile. Start searching today for boom concrete pumps that you could requirement for your cconstruction or industrial business.

your comment

your comment

-

Your small business is able to expand and to carry out this, you want a mobile asphalt plant. A stationary one will not do for that projects you possess planned starting from urban settings to rural ones beyond where your enterprise is located. Where can you find a mobile asphalt plant for sale?

Is it difficult to get a company that creates an excellent product? How could you tell once you have found this manufacturer or otherwise? Do people just leave reviews about these plants online? There are plenty of things to ask when you begin buying a mobile asphalt plant but really it is far from that difficult to purchase one.

You can get many decent manufacturers that have been making these plants for years right online. They have full specifications and photographs in the products they have and most of them could be shipped right to you. Because of this is can be possible to find a product in China and ship it for your needs in the US.

Mobile asphalt plants could be a great investment for just about any company. They allow you to cut back funds on overhead initially to get additional jobs farther away from where you are located. There are actually costs involved with transporting them however they are nominal in comparison to the money that you is likely to make.

They are available in standard models with three chassis and you could pick if you add on a silo for storage. Choose standard one-bin models or two split bins. They are capable of creating any hot asphalt mix for almost any job. Most tend not to require installing a basis like stationary machines do but even if some do, they generally feature your purchase.

You can find them at great prices on sale online. The most suitable choice is to purchase the merchandise you want from your manufacturer directly. This lets you make the most of any warranty or service plan that comes with the system. Learn more here.

An effective tip to go by is to find one used in order to save much more money. Buying used models from trusted manufacturers is a great way to cut costs and initiate out on your venture of expanding your small business to accomplish highway work, construction work or other projects.

These asphalt mixers are a great value since you can easily transport them wherever jobs require. Compare the makers online for the greatest dealer for you. Most of the top manufacturers have already been running a business for several decades. Some have even invented revolutionary mobile asphalt features.

They often have testimonials from satisfied clients on their own websites as well as photos of your asphalt mixing plants taking care of job sites. These are already popular in construction however are also utilized in manufacturing plants.

Compare manufacturers along with their prices for that size you want. Then, select 1 or 2 to e-mail to obtain additional details and specs from. Do not forget to question services plan, and you should not be shy about requesting information about used asphalt plants for sale. These are an excellent investment and you may purchase a great product easily and affordably online.

your comment

your comment

-

Mobile concrete batching plants allow construction companies to produce their own concrete on-site as an alternative to having it delivered. Different kinds of concrete can be produced just by varying the ratio of the things that are within the mix.

Using one of those batching plants could save a ton of money in comparison to the value of having concrete delivered from the ready-mix plant. Several of the money-saving advantages of using a concrete batching plant are outlined below.

There are a lot of disadvantages related to having ready-mix concrete delivered. In case the delivery isn't timed just right, workers find yourself standing around awaiting the concrete to come. As a businessman, this means that you are paying them for time, even though they aren't actually working.

With a concrete batching plant on-site, however, the workers will make the concrete every time they require it. Because of this they could continue working with no unnecessary delays. This could help you save a lot of money regarding your labor expenses. Instead of paying workers to stand around, you will be paying these people to work, allowing you to acquire more value for your money. View more here.

Mixing the concrete in the job site also brings about less waste. Workers can mix the actual amount of concrete that they can desire for the project. For that reason, there isn't any leftover concrete to get rid of. That isn't always true with ready-mix concrete.

When you have concrete delivered, it is actually tough to gauge just how much you will really need. Because of this, overages often occur. Which not only means you are wasting money concrete that you aren't using however, you also may need to pay to discard any excess. Avoiding waste not just offers a financial benefit for your personal business but can also be better for your environment, meaning that you could feel better about your organization practices.

Using an on-site portable batching plant can also help prevent difficulties with the standard of the concrete. If transportation delays occur due to heavy traffic, breakdowns, or another issues, water might need to be added in towards the concrete to really make it usable. Although this aids in preventing waste, additionally, it has one major unwanted side-effect: it negatively impacts the effectiveness of the finished concrete.

Once you mix the concrete yourself by using a batching plant that you have on the job site, you don't need to worry about delays. Because of this there is a whole lot more control over the strength of the finished concrete, which can help your projects come out far better.

A mobile concrete batching plant will save construction businesses money in a lot of different methods. For starters, it keeps workers from being forced to wait for a concrete being delivered. Instead, they can arrive at work without delay, which allows you to get more value for your wages you will be paying. It may also help prevent waste, that may prevent you from purchasing concrete that you simply don't need.

your comment

your comment

-

Portable cement mixers make quick work of mixing concrete. These machines are designed to mix every one of the ingredients automatically, eliminating the necessity to mix them manually. Automating the mixing process is far faster and much less labor-intensive than carrying it out by hand, which is the reason mixers such as these are so popular inside the construction industry.

Unfortunately, should your portable cement mixer for sale fails, it can slow down the concrete pouring process, causing delays. Additionally, it forces workers to set considerably more physical effort in to the concrete mixing process, which could leave them sore and tired in the end during the day.

Together with the right parts, most cement mixers may be repaired. Finding spare parts for mixers like these isn't easy, however. Since they are specialized pieces of equipment, you can't just run down to your nearby home improvement center and look for what you require. Instead, you should get them coming from a supplier who carries parts for construction equipment.

Getting a whole lot on the parts will help maintain the repair costs down. You can find a number of different tactics that you can use to save money on portable cement mixer parts.

One choice is to get hold of the company that manufactured your electrick cement mixer for sale directly. Manufacturers will frequently offer discounted parts to those who have purchased their equipment previously.

Shopping online can be another great option since it makes it easy to compare and contrast prices between different suppliers. Just search for the name or number of the part you need. Then, click through all the search results to determine what store offers the best price. Don't forget to accept shipping fees into mind, as well, because they can significantly increase the total price. This is especially true in case you are ordering the part from overseas.

If you really want to spend less, also you can look into buying used parts. Parts such as these are a bit harder to get. Usually, however, they can be extremely inexpensive. Just remember that they can not last given that a brandname-new part because they have previously experienced a considerable amount of wear and tear.

Seeking the name or quantity of the part that you require isn't easy. Start with checking the owner's manual to your cement mixer. If you can't find any information there, you can examine the web site of the manufacturer. Alternatively, you are able to get in touch with them directly for help. They must be more than happy to present you the part number to help you order what you need.

By using these tips, you should certainly save cash on parts for your personal portable cement mixer. There is no have to spend lots of cash to have the parts you need. So long as you shop wisely, you must be able to obtain your self loader concrete mixer back working for very little money. Despite the fact that tracking down parts could be a little bit of a hassle, repairing your cement mixer is much less costly than buying a replacement.

your comment

your comment

-

You need to make sure you get a good automatic brick machine for sale when you have a project that requires one to make bricks. There are a few different choices on the market available on the market. To locate what will probably work right for you, please read on to find out more.

You're going to have to discover what your choices are in relation to this sort of machine. A great way to learn what you can purchase is to apply a search engine website to look up "automatic brick machines" or anything along those lines. Once you get results, start putting together a long list of machines that you're interested in utilizing. Then, you may use that list to do a little more research about what your alternatives are. Keep reading to discover a bit more, however, before buying something so uncover more about your options.

Knowing what machines are out there, you're planning to want to find out what all of them cost. For this reason you're going to want to search for prices about the machines to have a sense of anything they cost typically. Try to find as much prices on a single machine since you can and you then must be able to use a better notion of such a fair price is usually to pay. Don't just purchase one without having done any more research, however, because price isn't the only thing you should try to find with regards to brick making machines.

Find several reviews that you can on these kinds of machine to understand if it's worth every penny or perhaps not. When you get a concrete block making machine that features a good price linked to it, then you're going to desire to find reviews on that machine to make certain it's the right choice to suit your needs. If you find that a device is cheap rather than perfectly reviewed, you should avoid buying it. Regardless of whether you're capable to save a ton of money by picking something using a bad reputation, that implies that you're planning to have issues with it making it not really worth the money.

Before you purchase from the seller, be sure that you can return the appliance if you're unhappy by using it for one reason or some other. For instance, if you purchase it and yes it doesn't make bricks the actual way it should as a result of malfunction from the machine, then you're planning to want to know available your money back because of it. Right once you get a brick machine you want to test it all out so you're able to get a refund if something is wrong by using it.

Now it needs to be clear what is required for you to find the appropriate automatic brick machine available for purchase. This really is something which costs money so you should be careful in regards to what you may spend. You don't desire to turn out spending over precisely what is fair for the machine you get.

your comment

your comment

-

Buying an asphalt drum mix plant can assist you offer better services to your clients. This could be the start of a prosperous business. However, you should make sure you purchase high-quality equipment that may continue for a long time. This short article explains how to find a reliable asphalt drum mix plant manufacturer.

The easiest way to achieve this research is to utilize an industrial directory or even a large global trading marketplace. Always search for manufacturers instead of retailers of such equipment. Buying straight from the manufacturer provides several positive aspects such as lower prices and much better customer services. The best places to seek out asphalt drum mix plants are AliBaba.com and AliExpress.com. These trading directories list a large number of companies willing to find potential clients online. These companies are in China, India or other countries in Asia, but this doesn't mean they can't provide you with the top-notch equipment and services you expect. They may be as reliable when your local equipment manufacturers. Additionally, they are less costly, since their operating and manufacturing prices are lower.

Direct comparison is another thing that can help you look for the best deal along with the most dependable provider. However, before proceeding to comparing quotes, you must do the research to create a shortlist of trustworthy companies. This means you need to take a look at their experience in addition to their results, in addition to their certifications along with their quality assurance policies. Keep in mind that your work doesn't end with purchasing the right equipment. Putting together your plant will require assistance from the producer, so you'll have to successfully pick a company that can present you with timely and effective services. Also, the constant maintenance and repair works matter a good deal, since they will make the visible difference between a plant that runs at full speed all year long and another that pauses production every other day for repairs. Learn more here.

When comparing solutions, do your greatest to rule out unreliable suppliers right from the start. This is simple to do is you search for client testimonials and reviews. Besides, business directories can help you make your choice, because they publish client ratings and reviews for those businesses in their database. This make sit simple to find out at a glance who deserves your trust and who doesn't. While you can depend on these client reviews to become real, you need to do your own personal research to view whether these firms comply with your personal requirements in terms of commercial conditions and excellence of their equipment.

The price of your equipment is also important, but it really shouldn't be the first and foremost selection criterion. If keeping your initial costs low means that you should compromise on the features or on the standard of your asphalt drum mix plant, you'll fail inside your endeavor of setting up a successful business. Always put money into reliable equipment, even if you want to find additional financing to get started on your projects. In time, your time and efforts will probably pay off.

your comment

your comment

-

As a tradesman, it’s important that I have got all of the best equipment and tools so I can complete my job to my customer’s satisfaction. Yesterday, I found out how the concrete mixer that I was using more than a couple of years had did start to become faulty. I personally use concrete mixers for most different areas of my company, thus I knew that we needed to get a quick and reliable replacement as soon as possible. Hence, here’s how some tips regarding getting reliable portable concrete mixer and pump quotations.

Considering I needed to change the concrete mixer which had broken at the earliest opportunity, I found myself keen to have as much quotes from reputable retailers. There are numerous reputable retailers during my area, though the prices that they offer sometimes can vary greatly. I often find out about other tradesman losing out by paying a lot of for equipment. Equipment can sometimes cost a lot of money, as well as the few extra hundred or thousand dollars paid for overpriced equipment can cause financial difficulties for a tradesman.

As a result, I made a decision to use extra challenging reliable and trustworthy quotations for concrete mixers and pumps. I wanted to have a new concrete mixer at the end each week, thus I found myself calling as much different retailers as possible during lunch breaks and in the evening. I realized that one of the better methods for getting reliable quotes is to directly call the retailer as well as ask specifically in regards to the prices that they are requesting certain designs and brands of concrete mixer and pump.

That which was most surprising for me was the point that the listed prices on the internet or perhaps in brochures are not always accurate. Usually, the retailer is able to offer a price that is certainly much lower compared to what they can be looking for in brochures or in television or internet advertisements. For this reason I realized how important it can be to call the retailer directly about what they can be selling and the way much they may be seeking each item.

Through making many different direct calls, I could make contact with sales individuals who were able to negotiate the price with me. They understood that I had been a tradesman and this it absolutely was vital i have a fair deal for your equipment which i was thinking about purchasing. Hence, by haggling a little bit I was able to get huge deductions about the original prices requested various sorts of concrete mixers and pumps. It was great as it allowed me not only to get reliable and recent quotations for these particular items, I found myself also capable of getting them at lowered prices. Get price details here.

Thus, through this technique of directly calling retailers I could get reliable quotations in addition to cheap prices. I believe that more individuals who will work inside my type of business needs to be proactive and look for new techniques for getting better deals on essential pieces of equipment including concrete mixers.

your comment

your comment

-

If you're hoping to find a self-loading concrete mixer on the market at the reasonable price, then you've come off to the right place.

In this particular guide, we're going to tell you some of the main things you'll want to look for inside a high-quality self-loading concrete mixer, and you will also find out more about where you may purchase these fantastic machines with a very affordable price indeed. That said, let's explore this issue in further detail.

Firstly, one of the best places to get these concrete mixers is by sourcing the maker online, because you will certainly make some excellent savings once you purchase directly from the manufacturer in this manner. Of course, lots of the best self-loading concrete mixers available for sale are being made in either India or China, and both these countries can sell the items online, which can be a very good way to help make real savings.

If possible, it's always a good idea to check out the country directly, as this will allow you to compare the numerous options that come with the models, and ultimately select one that will likely be best option to your construction business.

With regards to inspecting the numerous features these machines offer, it's worth noting that self-loading models are frequently the best choice to decide on, since the automatic loading, metering, mixing, and discharging ability make sure they are the right in one solution that may dramatically increase the productivity of your respective crew on virtually any worksite.

Of course, while you can find a array of small concrete mixers you could buy, it's safe to say that self-loading concrete mixers are the ultimate choice for any company or business that features a great need for high-quality concrete at a moment's notice.

Furthermore, these designs are very well planned out when it comes to efficiency, so they have numerous features that will make them surprisingly intuitive as well as simple-to-use. Ultimately, because of this your team won't need a lot of training to understand their operation, and you'll soon be reaping all of the benefits and increased productivity these machines will permit for.

On many occasions, you will be shocked and delighted by just how much labor these appliances can help to save, especially if your crew is commonly used to utilizing a manual concrete mixer.

Furthermore, once this equipment is set up correctly, they will likely reliably discharge an extremely high-quality mix that'll allow you to use a consistent experience during the entire entire project. If you've ever worked on a task site before and located that obtaining a reliable blend of concrete has been a real hardship, then these machines are the most effective solution for solving the issue for good. View more here.

It's also worth noting that many of the best machines use a surprisingly short mixing cycle because of the size, therefore you won't be left waiting around to the mix to get ready.

Overall, making an investment in one of those self-loading concrete mixers is a wonderful option for any company that's attempting to boost their productivity throughout the construction industry.

your comment

your comment

-

Do you want to turn into a renowned concrete block supplier and trying to find a machine that will assist in order to meet the needs from the customers? You have to monitor the options and operations of your machine that you are likely to buy as there are fully automatic, semi-automatic, and manual machines which one can find on the market. Ideally, you ought to look to obtain a fully automatic machine. It costs more initially however the features that you get will be worth every penny you would spend. Discussing the functions, let’s look into some of the top features which a concrete block machine needs to have:

1.Method utilized to have the blocks

Hydraulic pressure is utilized to make the concrete blocks. The most effective machines available in the market utilize this method mainly because it helps to produce the maximum output in the machines. You will find machines that utilize other methods also yet it is easier to purchase a machine which utilizes hydraulic pressure technology. It not merely produces more concrete blocks but the grade of the blocks is also superior.

2.Raw materials required

Ideally, every concrete block machine needs three ingredients that are lime, dust, and fly ash. However, it is important to locate a machine that can help to comprehend the precise proportion of raw materials that ought to be employed to produce good-quality concrete blocks. Experienced workers will know regarding the right proportion but in case you are working with a new team, it may well become hard to comprehend the exact quantities of raw materials required to make a certain number of concrete blocks from the machine. Moreover, the machine should mix all of the ingredients on its own. That is why it is advisable try using a fully auto brick machine otherwise, you would probably experienced to utilize a skilled worker who is familiar with the proportions of raw materials needed to make concrete blocks.

3.Expected output

Different machines produce different quantities of concrete blocks dependant upon their size and capacity. But there are machines that have the capability to produce no less than 500 blocks an hour to around 4000 blocks each hour. One good reason why you need to decide to purchase a machine that has such a wide array of output is that you may control the output as and when you need. With semi-automatic or manual machines, it might be very difficult to limit the output once you devote all the raw materials.

4.Kinds of block

Being a concrete block manufacturer, you will definitely get a number of requests in terms of the style of the concrete block. So, it will probably be safer to get a machine that comes with both curbstone and interlock block types. This will provide a slightly different look to the blocks when they are made.

The hollow block machine for sale will surely cost more but they will not burn an opening in your pocket though. Most importantly, the price of the appliance will come up within a year of supplying the concrete blocks because of its popular demand.

your comment

your comment

-

The newest developments in the technology that underpin concrete pumps has resulted in the introduction of diesel powered concrete pumps. These pumps can provide a more efficient result in managers and operators around the world that are given the job of making sure a development or construction is finished by a deadline. In relation to concrete pumps that happen to be powered by diesel, they certainly aren’t anything new for that industry. However, recent technological developments have made this type of pump more powerful and desirable than before. Thus, here’s some essential information regarding diesel powered concrete pumps.

One of the main items that I want to stress about this particular type of concrete pump is that it is certain to get a lot more costly to purchase them. Simply because as more people set out to understand that the latest and improved versions of diesel powered concrete pumps that can easily be bought right now can greatly benefit their operations, the sellers of the pumps is going to be inclined to charge higher prices. The reason being there are far more firms that need to make heavy consumption of these pumps since there are new manufacturers of such diesel powered pumps.

Hence, I currently advise that more businesses check out these concrete pumps for their projects. I do believe that all of the new attention which is being paid to this kind of pump is well deserved with the wonderful benefits a lot of companies have been capable of experience through using them. However, I would urge that anyone trying to procure diesel powered concrete pumps with regard to their projects achieve this using the right mindset and tactics. A lot of businesses that are producing these pumps are starting to charge very unreasonable prices for that portable concrete pumps, meaning that buyers need to start making use of the right negotiating tactics to ensure they don’t result in an unfair deal.

One method to make sure that bad deal isn’t agreed upon regarding a transaction involving these pumps is always to always delay responses towards the seller in the pumps. Delayed responses are a very important and effective tactic that we have utilized often times during the entire projects We have handled. If you give you a price to get a given group of pumps which can be initially rejected, the manufacturer will often come back to you using a counteroffer. Getting a while to answer the counteroffer implies that you convey a note on the seller that you have other choices and you are not dependent on the sale dealing with. From the mind from the seller, they will get a greater incentive to negotiate further and compromise a little more due to this. Get more here.

Tactics including employing a delayed reply to counter offers is a terrific way to make certain that any deal that is decided regarding diesel powered concrete pumps is fair. As mentioned, the current business climate allows you for companies to fall under pitfalls that cause them to pay excessive for any given pump. There are numerous great tactics, including the ones that I presented in this post, which can help ensure a favorable deal.

your comment

your comment

-

A concrete pump does a fantastic job of mixing cement with some other aggregates to produce a solid mix of concrete necessary for various construction projects country wide. The mixer truck will likely then transfer the concrete mixture towards the location where it really is required. Electric pump mixers have grown to be increasingly popular in this day and age due to the numerous benefits made available from them. These mixers are economical, clean, and eco-friendly compared to diesel mixers. Electric Concrete Pump Mixers are utilized in a variety of construction sites including building, dam, bridge, and hydropower engineering. Here are some of the most essential benefits of Electric Concrete Pump Mixer.

The electric pump is powered by electricity. This particular pump can be used in every section of the country provided there is certainly access to electricity in the area. This is why most construction site owners and managers prefer this type of concrete pump mixture. On the flip side, this kind of machine is very compact in comparison to diesel machines. Hence, they may be taken up any area where it might be challenging to carry bulky machines. The electric pump is far more efficient and simple to operate compared to a diesel machine. Time that takes to blend the fabric is much less in comparison to other concrete pumps in the marketplace. It is actually quite durable too. That is certainly why should you consider investing in this particular machine should you own or run a construction site. Check more info here.

The speed or pouring rate of concrete is very full of the electric pump mixer. As a result, the productivity of the site would increase over time. The truth is, a manually operated pump may need extensive training of your labor force to use the machine properly. But an electric powered pump doesn't require much training. Because the electric pump is just not that bulky, it may be easily moved from spot to place. The pump uses less water and provides out high quality concrete when compared with the majority of machines. It may help preserve the concrete strength and gives an improved quality product.

Alternatively, electric pumps require less maintenance compared to a diesel pump. It really is quite durable too. These are some of the important great things about a power concrete pump. For you to do the studies properly before choosing a good electric pump to your construction site. There are many brands and kinds of pumps available on the market. But each one of these items are not came up with the same. There are actually quality pumps along with cheap ones available on the market. Be sure to invest in a top brand when purchasing a small concrete mixer and pump. That way you will definately get a much better ROI for the money you spend on the machine.

In summary, electric concrete pumps have numerous benefits in comparison with other pumps. That may be why you ought to invest in this pump for your construction project. The above mentioned read offers information about the advantages of this sort of pump.

your comment

your comment

-

Are you looking for an understanding for any business which includes the potential to earn a lot of profit? Do you need to have the capacity to make items that are in high demand? In that case, you really should consider purchasing a hollow concrete block making machine.

As you may guess, these machines are created to automate the entire process of making hollow concrete blocks. Even though the production capacity of those cement block brick making machine can vary based on their size, they make it possible to make a huge number of blocks in a relatively short period of time. These concrete blocks can then be sold to contractors or even to most people, allowing you to earn lots of money.

Hollow concrete blocks can be utilized in numerous alternative methods. Within the construction industry, they are usually used for building foundations. Additionally, they can be used for constructing exterior walls and building partition walls. Concrete is very durable and will be sealed to prevent moisture from getting into, making these kinds of blocks a great choice for building underground structures or walls that will be exposed to numerous water.

These concrete blocks also can be used for building fences, walls, or barriers. When stacked in addition to one other, they create a clean, utilitarian look. Depending on how they are used, they are often both functional and attractive.

Homeowners likewise use these blocks for various different applications. As an example, they may sometimes place a pair of these concrete blocks on to the ground and set up a board in addition to them, connecting them together. This results in a makeshift shelf or coffee table that has an industrial vibe. Click here now.

Concrete blocks will also be a common selection for gardening and landscaping applications. They can be used as everything from creating raised flower beds to building retaining walls.

One of the reasons why hollow concrete blocks are incredibly popular is because are affordable. The cavities in the blocks help minimize the amount of concrete that is needed to ensure they are. Because of this, their production pricing is relatively low. This savings may be passed on the customer, providing them access to the building materials they need at a price that they may afford.

The hollow chambers inside of the blocks also help in keeping them from being too heavy. When you have ever attempted to lift a solid bit of concrete, you realize precisely how heavy it might be. By leaving hollow cavities inside the concrete blocks, it may help keep how much they weigh down as far as possible. As a result moving and lifting them far more manageable.

Investing in a hollow concrete block making machine a very good idea if you wish to set up a profitable business. Because these blocks have been in such popular demand, you shouldn't possess trouble finding customers to sell these to when they are completed. As an added bonus, the machine made bricks in bangladesh that are employed to make these blocks are typically quite affordable. This means that you don't require a lot of capital to have your small business operational.

your comment

your comment

-

Operating a mixing plant might be exciting, but for a lot of people they generally do not realize their are different kinds of plants. This is the time people should understand about the three main classes that are present with a bitumen mixing plant. By knowing about this, it is going to make it easier for individuals to know if the plant is a they are going to enjoy working at as well as one that is going to require considerably more in the form of maintenance than what people think these are going to need to deal with.

Batch heater varieties of bitumen mixing plant are precisely what the name will make it appear to be it is. It is a plant that includes a heater that is going to consider the materials from multiple resources and also heat them up to and including set temperature. At the same time this will likely be using the heated materials they may have and putting them out to the mixers which will mix in the aggregates and also other materials that are going to be used to complete the asphalt. However, this sort of plant is often the required starting point to earning the asphalt.

Semi-continuous is the type of plant that is going to be applied for mixing the materials on a basis that can have some intermission with them. Using this method the materials is going to be mixed together, nonetheless they might not be mixed up completely to get a final product. So this is a method that is going to help individuals getting to have the materials partially mixed and get them finished mixing at work site. So men and women enjoy the fact that this can be a mixing process that will make it easier to allow them to complete the job.

Continuous mixing plants are another type of plant and one of the most common ones that folks are employed to seeing. Using this type of plant, it is different than the batch plants since this is a plant that will be making the asphalt in a manner that it will almost certainly constantly be producing asphalt. These plants will be the common ones that people are utilized to seeing and frequently the particular asphalt mixing plant that folks must have if they are thinking about making roads or other items which will require asphalt upon an almost constant basis.

Having the ability to know of the three main classes of bitumen mixing plants is a great thing. However, what folks must realize is this really is a lot harder to examine compared to what they might think. By obtaining a broad idea around the three types of plants, though, it is going to be rather easier for people to discover the right plant and know that it is going to meet their demands. Without it information, people may struggle to have the right plant put in place or perhaps order their next batch of asphalt in the right kind of company. View this company.

your comment

your comment

-

An asphalt batch plant is utilized to manufacture asphalt as well as other types of coated road stone that are often known as asphalt concrete. Asphalt concrete is manufactured using numerous materials like a variety of aggregates, sand as well as a filler. The filler used is generally stone dust. These aggregates are heated and coated having a binder which can be bitumen-based or tar-based. Asphalt batch plants are extensively utilized for road construction projects around the world. This informative article provides an overview of the countless features of asphalt plants for sale.

The asphalt plant is made up of cold aggregate supply system, coal burner, dust collector, vibrating screen, drum dryer, hot aggregate elevator, weighing & mixing system, filler supply system, bitumen supply system, and asphalt storage system. Every one of these components are made of the best to assure the complete quality of the asphalt mixture. It will also decrease the harmful negative effects of asphalt in the environment. For this reason it is crucial that you decide on a very high-quality asphalt batching plant when manufacturing asphalt for your road construction project. View more info here.

There are numerous types of asphalt plants available on the market. A batch heater plant operates materials from numerous cold feed hoppers towards the heater drum. Thereafter, the batch is heated into a certain temperature. The screening of the hot aggregate into several hot bins happens after that. All these hot bins will release a certain amount of aggregate to a weight hopper. It will then be discharged into the mixing drum. The binder and filler are added there. This blend is discharged into the delivery vehicles. The batch heater plant is normally used where short production runs are typical. There is also mobile batch heater plants for this function.

The asphalt drum mix plant a.k.a continuous asphalt plant is some machines that are utilized to produce asphalt. This really is a traditional type of asphalt plant that is different from the asphalt batch mix plant. Asphalt plants are extremely popular nowadays. They are most commonly useful for numerous rural and city road construction projects. There are lots of businesses that manufacture and then sell this kind of equipment. If you plan to buy an asphalt plant, you should do your homework first.

There are several manufacturers that produce this kind of equipment. But all of these services will not be top-notch. This can be why should you do your homework when looking for the most effective asphalt plant manufacturer in the marketplace. The internet changed the way in which people do business currently. You see many asphalt plant manufacturers online nowadays. The majority of these companies have professional websites that describe their items. This really is the best way to get all of the information in regards to the best asphalt plant available on the market.

To conclude, if you are looking to the many advantages made available from an asphalt batching plant, you have come on the right place. These small portable asphalt plants are extensively employed in road construction projects. The aforementioned article gives a comprehensive summary of the main great things about an asphalt plant.

your comment

your comment

-

Many builders find portable concrete pumps a lot better than stationary or fixed ones. This is one of the reasons why such gear is very popular among constructions companies. This article explains where to locate a transportable concrete pump available for purchase to incorporate more flexibility to the own business and to broaden the plethora of projects you can work towards.

The good news is you could find all kinds of small concrete pumps available for sale online, on a variety of websites. The not so good news is the fact you'll have to undergo your own research to narrow down your available choices to one of the most reliable ones. Let's see how this can be achieved the simplest way.

To start with, be sure you understand the non-negotiable features of your future equipment. Also, decide upon a financial budget range. This would let you avoid putting things off researching pumps that don't match your specific criteria. You should probably appraise the available space for storing where you want to maintain your pump when not in use.

If you don't mind buying your machine from China manufacturers, you may be able to find it on AliBaba, the largest global trading directory in thee world. This site connects sellers in a variety of countries in Asia with potential customers from around the world. There are a few great benefits of using such marketplaces when shopping around for industrial equipment and machines. One of these brilliant advantages is that you see the prices of all equipment on the same page, with specifics about the sellers along with details about the warranty of such machines.

Another advantage of using marketplaces is that you may compare offers from different manufacturers and never have to visit multiple websites. All you should do is to decide on the products you want to compare as well as to generate a next to each other comparison table. AliBaba, for instance, allows you to soon add up to 20 listings for your comparison sheet.

When searching for a portable concrete pump on the market, you should be careful, as not every sellers are equally reliable. Typically, it's advisable to buy straight from a manufacturer, to be able to reap the benefits of better customer services and minimize prices. Whenever feasible, avoid the middleman, particularly when considering about expensive equipment and machines. You'll reduce costs and you'll possess the peace of mind that you'll find support and help, should you really encounter any post-sales issues.

Bear in mind to inquire about the sellers concerning their quality assurance certifications and procedures. Also, remember that you should check whether their concrete pumps are compliant with your local regulations. It's always safer to understand that you're on the safe side when it comes to legal requirements.

Once you come up with a shortlist of 3 or 4 names of reliable providers, it can be a chance to ask every one of them to get a quote. Compare these quotes carefully to select the one who matches your needs while offering the finest value. Buying constructions equipment online is increasingly simple before. Check more info here.

your comment

your comment

-

In case you have ever seen road construction crews that are fixing certain aspects of the street, perhaps where potholes have appeared, and even if they are laying out a whole new segment in the road itself, they are likely to use something called asphalt. This really is a substance which is a blend of gravel or sand, in combination with dark bituminous pitch. It is extremely common, used in most countries which may have road systems, however it can be used for roofing and flooring too. You will discover a certain sort of asphalt called hot mix asphalt, or HMA, which happens to be about 95% gravel, combined with precisely what is called asphalt cement. There are actually factories that produce this substance, as well as the smell might be detected for miles. There are some dangers associated with this particular process that we will discuss, potential issues because of living near a hot mix asphalt plant.

What Exactly Is A HMA Plant?

This can be a industrial plant which comes in many different styles and sizes. By way of example, a batch heater is really a mobile plant that was designed to superheat a hot aggregate material that can then send the molten product right into a hopper along with a mixing drum. In addition there are continuous asphalt plants for sale, referred to as a drum mix plant that is certainly also effective at producing asphalt. This is much more of a regular location or apparatus for creating asphalt on a regular basis which could then be moved to a hot storage unit to keep it hot and prevented from settling. These HMA plants are a very necessary aspect of any large road development company that operates at a county or state level. A lot of asphalt must be produced every year to take care of the deterioration of the infrastructure of any country, maintaining the conditions in our roads upon which thousands of people continually drive on.

Hazards Of A Hot Mix Asphalt Plant

The main danger connected with HMA plants is specifically related to the fumes. There may be some thought that it must be particularly dangerous for kids as it can have an adverse impact on their lungs and ultimately their development. Carcinogens have been associated with the emissions that happen to be produced along the way of producing asphalt. The ones that are now living in close proximity to the locations where asphalt is continually produced have a higher risk of developing cancer as outlined by some studies. With that being said, if exposure is short-term, even when you are inside the immediate area, there is certainly likely no unwanted effects that will be measurable. It is not necessarily like aquifers which were contaminated as a result of using chemicals for drilling since the atmosphere is mobile, and continuous amounts of emissions due to asphalt production will never linger of sufficient length to cause any long-term problems. View more info here.

Although there are several dangers linked to the creation of asphalt using HMA plants, it can be unlikely that even long term exposure may cause competitive problems. It is actually simply around the safe side to step away from any sort of factory which produces emissions of any type, and knowing the hazards associated with long-term exposure to bituminous based asphalt will almost certainly prevent health problems from occurring.

your comment

your comment

-

Once we consider traditional concrete pouring methods, what one thinks of? Your thinking buckets overflowing with heavy wet concrete, wheelbarrows with flat tires, as well as the backbreaking manual labor included in hauling wet concrete up multiple sets of ladders, right? The good thing is that modern automatic concrete pumps can take away the labor-intensive natural of pouring concrete overnight. That is among the various benefits of purchasing a China concrete mixer pump.

For many individuals, it's easy to imagine how physically demanding conventional methods of transporting concrete around a construction site are. Luckily, automatic concrete mixer pumps are becoming a lot more affordable, as being a bigger variety of manufacturers enter into the marketplace. Because of this even small construction firms are now able to take advantage of the increased productivity rates modern concrete pumping equipment affords an operation. The expense of mixer pumps from Chinese sellers especially are really reasonable - even though shipping charges, import taxes, and forex fees are made up.

When construction workers get access to a concrete pump, the labor intensity and speed of distributing wet concrete to where it's required are generally reduced significantly. There are actually, obviously, a multitude of different concrete mixer pumps available for sale, including boom pumps and mini concrete pumps. Furthermore, construction companies that have limited funds for investment in modern machinery can explore the used concrete pump marketplace online. It may possibly surprise many regarding how many refurbished portable pump units are advertised on online classified platforms presently.

Speaking about concrete boom pumps, they represent a very good investment potential for mid to large-sized construction firms. The robotically controlled arm and associated piping located on boom pumps mean they may be ideally best for multi-level building construction projects. Lots of people wrongly assume that concrete pumps could only transport wet concrete laterally, but this is not the case with boom concrete pumps that will move the wet material in all of the directions, including vertically.

Boom concrete mixer pumps from China have extendable, foldable, remotely controlled arms (booms) in which a wide durable pipe is attached. The pumping device on the base of the arm can be diesel or electric powered. With regards to construction firms that work on a lot of remote building projects, a diesel-powered concrete boom pump will probably be the wiser investment choice. Meanwhile, for construction businesses that take on building projects in confined urban areas, electric-powered concrete pumps could be the smarter purchasing choice. Check more info here.

The advantages and disadvantages of diesel-powered versus electric-powered concrete mixer pumps have been discussed in great detail in several online articles. To be honest that electric pumps produce less fumes and noise pollution, while diesel pumps are more powerful and designed for operation in harsh natural environments. Another benefit of diesel-powered pumps is because they don't demand a local high-voltage electricity source for operation. Thus, they are good for remote and offshore construction projects. At the conclusion of the time, it's around buyers to weigh up the pros and cons of all different concrete pumps in the marketplace. View more here.

your comment

your comment

-

Ketika Anda membeli peralatan industri seperti pompa beton kecil, Anda mungkin bertanya-tanya bagaimana perbandingannya dengan produk serupa lainnya. Ada beberapa pompa beton yang dapat dijual hari ini, sebagian besar berukuran sangat kecil, sedangkan yang lain dilengkapi untuk pekerjaan yang lebih besar. Untuk menemukan daftar pompa beton yang akan dijual ini, Anda mungkin harus mencari di internet. Sebenarnya mungkin saja ada bisnis lokal yang juga dapat memberi tahu Anda apa yang dapat mereka jual untuk memberikan pemikiran yang lebih baik tentang apa yang tersedia. Informasi berikut akan menunjukkan kepada Anda perbedaan antara pompa beton kecil standar, khususnya dibandingkan dengan yang lain yang juga dapat dipasarkan.

Apa Perbedaan Ukuran Untuk Pompa Beton?

Ada berbagai ukuran yang bisa diproduksi oleh bisnis yang kebetulan berada di industri beton ini. Mereka memproduksi peralatan industri ini untuk kontraktor, pekerja semen, dan orang lain yang tentunya menuangkan beton secara rutin. Pompa yang portabel cenderung berukuran paling kecil, meskipun ada beberapa pompa stasioner berukuran sedang hingga kecil pada saat yang bersamaan. Yang terbaik adalah pompa beton yang dirancang untuk bekerja sama dengan pabrik pencampur beton stasioner besar yang dapat menghasilkan 1000 galon dengan bahan ini.

Akankah Diperpanjang Untuk Mendapatkannya?

Sebelumnya, sebenarnya lebih sulit mendapatkan banyak ukuran yang berbeda. Anda dibatasi oleh apa yang disediakan oleh produsen di kota Anda. Saat ini, adalah mungkin untuk menemukan banyak perusahaan online yang menawarkan kepada Anda semua yang sedang dijual. Mereka bisa memiliki 10 atau bahkan lebih, dan juga membandingkan ini dengan yang dijual oleh bisnis lain, Anda akan melihat jumlah sebenarnya. Secara keseluruhan, seharusnya tidak lebih dari beberapa jam untuk mendapatkan daftar yang cukup besar dari pompa beton kecil yang saat ini tersedia untuk dibeli. Anda dapat membandingkannya dengan ukuran lain dan membuat keputusan tentang mana yang terbaik untuk bisnis pribadi Anda.

Bisakah Anda Benar-benar Mendapatkan Harga Dengan Daftar Ini?

Sangat mungkin untuk mendapatkan daftar dan harga. Ini tentu saja biasanya berapa banyak dari perusahaan ini yang menjual pompa beton yang mereka tawarkan. Sebagian besar waktu, semua yang mereka jual kemungkinan besar akan ada di situs web mereka, termasuk tautan yang memungkinkan Anda melakukan pembayaran untuk melakukan pembelian. Rincian kontak juga akan tersedia. Jika Anda tidak melihatnya, ini adalah ukuran yang sesuai, Anda selalu dapat menghubungi mereka secara langsung. Mereka mungkin memahami secara khusus hal-hal yang mereka miliki, dan dengan mendapatkan informasi orang dalam ini, Anda mungkin akan mendapatkan kesepakatan yang luar biasa tentang hal yang Anda inginkan.