-

In the construction industry, selecting the right equipment involves careful consideration of various factors, including cost efficiency. Evaluating investments ensures that construction companies make informed decisions that align with their budget and long-term goals.

Mobile wheeled crushers and tracked crushers are both popular choices for crushing operations in construction projects. While wheeled mobile crushers offer flexibility and maneuverability, tracked crushers provide enhanced stability and traction on challenging terrain.

Cost Efficiency of Mobile Wheeled Crushers

Mobile wheeled crushers generally have a lower initial purchase cost compared to tracked crushers. This makes them an attractive option for construction companies with limited capital or those looking to minimize upfront expenses.

Although mobile wheeled crushers may have lower initial costs, they can incur higher operating and maintenance expenses over time. Factors such as fuel consumption, tire wear, and maintenance requirements should be carefully considered when evaluating the overall cost efficiency. Find more info about wheeled type mobile crusher here: https://aimixglobal.com/mobile-crusher-plant/.

Despite potential higher operating costs, mobile wheeled crushers may offer long-term value and a favorable return on investment in certain scenarios. Their versatility and ability to quickly relocate between job sites can result in increased productivity and project efficiency, ultimately contributing to cost savings over time.

Cost Efficiency of Tracked Crushers

Tracked crushers typically have a higher initial purchase cost compared to mobile wheeled crushers. However, this investment may be justified by their superior performance and durability, especially in demanding operating conditions.

While tracked crushers may have higher initial costs, they often boast lower operating and maintenance expenses in the long run. The robust construction and advanced technology of tracked cone crusher minimize downtime and reduce the need for frequent repairs, resulting in overall cost savings.

Tracked crushers offer long-term value and a promising return on investment due to their durability, reliability, and efficiency. Their ability to tackle challenging terrain and maintain consistent performance makes them an attractive option for construction companies seeking to maximize productivity and minimize operational costs.

In conclusion, evaluating the cost efficiency of mobile wheeled crushers and tracked crushers is essential for making informed investment decisions in the construction industry. While wheeled crushers may offer lower initial costs and greater flexibility, tracked crushers provide superior performance and durability in demanding environments. By considering factors such as initial purchase cost, operating expenses, and long-term value, construction companies can select the most cost-effective crushing solution that aligns with their project requirements and budget constraints.

your comment

your comment

-

Portable impact crushers have become indispensable tools in various industries, offering versatility and efficiency in crushing applications. However, to ensure optimal performance and longevity, careful consideration is given to their design and construction. This article explores the key considerations taken into account during the design and construction of portable impact crushers to minimize downtime and facilitate quick maintenance and repairs.

Design Considerations for Minimizing Downtime

Robust Construction and Materials

One of the primary considerations in the design of portable impact crushers is the incorporation of robust construction and high-quality materials. These crushers are subjected to significant wear and impact forces during operation, necessitating durable components to withstand the rigors of crushing various materials. Manufacturers utilize advanced engineering techniques and premium materials, such as high-strength steel alloys and wear-resistant coatings, to enhance the durability and longevity of portable crusher. By employing robust construction practices, manufacturers ensure that their crushers can withstand heavy-duty use without succumbing to premature wear or damage, thus minimizing downtime.

Accessible Design Features

In addition to robust construction, accessibility is another crucial factor in minimizing downtime for maintenance and repairs. Portable impact crushers are designed with accessible components and service points to facilitate quick and efficient maintenance tasks. Features such as easily removable access panels, strategically located inspection doors, and integrated service platforms allow technicians to access key components and perform routine inspections and repairs with minimal downtime. Furthermore, manufacturers incorporate user-friendly design elements, such as color-coded components and intuitive maintenance procedures, to streamline maintenance operations and reduce the risk of errors. By prioritizing accessibility in the design phase, portable impact crushers enable timely maintenance interventions, thereby minimizing downtime and optimizing operational efficiency.

Maintenance and Repair Facilitation

Modular Components and Easy Access Points

To further facilitate maintenance and repairs, portable impact crushers are often equipped with modular components and easy access points. Modular design allows for the swift replacement of wear parts, such as impact bars, blow bars, and liners, without the need for extensive disassembly or specialized tools. Additionally, manufacturers design crushers with strategically positioned access points, such as hatches and service doors, to facilitate routine maintenance tasks, including lubrication, belt tensioning, and inspection of critical components. By incorporating modular components and easy access points, mobile stone crushing machine empower maintenance personnel to swiftly address issues and perform preventive maintenance measures, thereby minimizing downtime and maximizing uptime.

Comprehensive Maintenance Planning and Support

In addition to design features, manufacturers provide comprehensive maintenance planning and support services to ensure the ongoing reliability and performance of portable impact crushers. This includes the development of tailored maintenance schedules, recommended spare parts inventories, and technical support resources to assist operators in optimizing crusher performance and longevity. Moreover, manufacturers offer training programs and technical seminars to educate operators and maintenance personnel on best practices for maintaining and repairing portable impact crushers. By equipping operators with the necessary knowledge and resources, manufacturers empower them to proactively manage maintenance activities and address potential issues before they escalate, thereby minimizing downtime and maximizing crusher availability.

Conclusion

In conclusion, the design and construction of portable impact crushers are carefully tailored to minimize downtime and facilitate quick maintenance and repairs. Through robust construction practices, accessible design features, modular components, and comprehensive maintenance planning and support, manufacturers ensure that their crushers deliver reliable performance in various crushing applications. By prioritizing uptime and operational efficiency, portable impact crushers continue to serve as indispensable assets in industries ranging from construction and mining to recycling and demolition. Find more details here: https://aimixcrusherplant.com/crusher-plant/.

your comment

your comment

-

Granite, a popular and durable natural stone, is composed of various minerals that influence its properties and characteristics. Understanding how the mineral composition of granite affects the crusher selection process is essential for optimizing crushing operations. Let's explore the relationship between granite's mineral composition and the selection of crushers.

Impact of Mineral Composition on Crusher Selection

Influence of Hardness and Abrasiveness

The hardness and abrasiveness of granite's mineral components significantly impact the selection of crushers. Minerals with higher hardness, such as quartz and feldspar, require rockcrushers with greater crushing strength to break them down effectively. Similarly, minerals with high abrasiveness, like garnet and magnetite, necessitate crushers with durable wear-resistant components to withstand the abrasive wear during crushing operations.

Consideration of Mineralogy and Texture

The mineralogy and texture of granite play a crucial role in determining the suitable crusher for processing. Variations in mineral composition, such as the presence of mica or amphibole, can affect the material's brittleness and fragmentation behavior during crushing. Texture differences, such as grain size and shape, also influence the crushing process by affecting particle interlocking and material flow through the crusher chamber.

Effects of Mineral Composition on Crushing Efficiency

The mineral composition of granite can influence the efficiency of the crushing process. Certain minerals may exhibit cohesive or adhesive properties, leading to material buildup and blockages in the crusher. Additionally, variations in mineral composition can affect the fragmentation pattern and particle size distribution of the crushed product, impacting downstream processing and product quality. View more info about crushers here: https://aimixglobal.com/limestone-crushers/.

Factors to Consider in Crusher Selection Based on Mineral Composition

Matching Crusher Strength with Mineral Hardness

When selecting a crusher for granite processing, it's essential to match the crusher's strength with the hardness of the mineral components. Harder minerals require crushers with higher crushing forces to break them down efficiently without excessive wear or damage to the equipment. By matching the crusher's strength with the mineral hardness, operators can ensure optimal performance and longevity of the crushing equipment.

Choosing the Right Crushing Chamber Configuration

The mineral composition of granite influences the selection of the appropriate crushing chamber configuration. Different crushers offer various chamber options, such as standard, fine, and coarse configurations, each suited to specific mineral compositions and crushing requirements. By choosing the right chamber configuration, operators can optimize crushing performance and achieve the desired end product size and shape.

Selecting Suitable Wear Parts for Specific Mineral Compositions

Wear parts, such as crusher liners and impact bars, play a vital role in crushing operations, particularly when processing abrasive minerals like granite. The mineral composition of granite determines the type and extent of wear experienced by the granite jaw crusher components. Therefore, selecting wear parts with the appropriate material composition and hardness is crucial for maximizing wear resistance and extending the service life of the equipment.

In summary, the mineral composition of granite has a significant impact on the crusher selection process. Factors such as hardness, abrasiveness, mineralogy, and texture influence the choice of crushers and crushing parameters. By considering these factors and selecting the right equipment and wear parts, operators can optimize crushing efficiency, minimize downtime, and achieve superior product quality in granite processing operations.

your comment

your comment

-

Mobile crusher plants have revolutionized industries like mining, construction, and demolition by providing on-site crushing capabilities. However, the size and weight of these plants significantly impact their transportability and suitability for diverse job sites. Let's delve into how these factors play a crucial role in determining the practicality and efficiency of mobile crusher plants.

Introduction

In today's industrial landscape, mobile crusher plants stand as versatile solutions for various applications. These plants, equipped with crushers and screens, can process materials directly at job sites, eliminating the need for transportation to centralized facilities. As such, understanding the nuances of the crawler mobile crusher machine transportability and suitability is vital for optimizing operational efficiency.

Impact of Size and Weight on Transportability

Mobile crusher plants come in a range of sizes and configurations, each with its own set of advantages and limitations. However, the size and weight of these units significantly influence their transportability:

Compactness and Maneuverability

The compactness of a mobile crusher plant is paramount for ease of transport. Smaller units are inherently more maneuverable, allowing them to navigate through tight spaces and rugged terrain with relative ease. Conversely, larger plants may require specialized transportation equipment and permits, adding complexity and cost to the logistics.

In congested urban environments or remote job sites with limited access, the ability to maneuver swiftly can make the difference between timely project completion and costly delays. Learn more details here: https://aimixcrusherplant.com/mobile-crushing-plant/.

Transport Logistics and Costs

The weight of a mobile crusher plant directly impacts the logistics involved in its transportation. Heavier units necessitate stronger trailers or trucks for hauling, potentially requiring oversized load permits and specialized carriers. These factors contribute to higher transportation costs and may pose challenges in adhering to regulatory requirements.

Additionally, the distance between job sites and the availability of suitable transportation infrastructure further influence the feasibility of transporting heavy equipment.

Suitability for Different Job Sites

Beyond transportability, the size and weight of a mobile crusher plant also dictate its suitability for various job sites:

Terrain Considerations

Job sites encompass diverse terrains, ranging from flat plains to rugged mountains and dense forests. The size and weight of a mobile crusher plant must align with the terrain's characteristics to ensure safe and efficient operation. For instance, compact units excel in navigating uneven terrain, whereas larger plants may struggle or require extensive site preparation.

Furthermore, considerations such as ground stability and slope gradients play a crucial role in determining the feasibility of deploying heavy machinery in challenging environments.

Accessibility and Setup Requirements

Access to job sites can vary significantly, posing unique challenges for deploying mobile crusher plants. Lighter, more compact units are often favored for projects in remote or inaccessible locations, where conventional transportation methods are impractical. Moreover, the setup requirements of the plant, including assembly and disassembly procedures, must align with the site's logistical constraints to minimize downtime and optimize productivity.

By evaluating these factors comprehensively, operators can select the most suitable mobile stone crusher and screening plant for each job site, ensuring seamless integration into existing workflows.

In conclusion, the size and weight of a mobile crusher plant are critical considerations that influence its transportability and suitability for diverse job sites. By carefully assessing these factors and their implications, industry professionals can make informed decisions to enhance operational efficiency and project outcomes.

your comment

your comment

-

A concrete pump is a remarkably versatile machine, capable of significantly impacting project timelines, reducing completion from days to mere hours. The ability to pump concrete precisely to designated locations enhances the efficiency of various tasks. However, to ensure optimal performance and longevity, it’s crucial to invest in top-notch concrete pumping equipment. To evaluate the quality of such equipment, it’s essential to grasp the fundamentals of how they operate.

How Concrete Pumps Work

Concrete pumps operate on a simple principle, featuring a twin-piston pump design. As one piston moves in the opposite direction of the other, it extracts and pumps concrete. The speed of the pump directly influences the delivery speed of the concrete. Additionally, the size of the pump is a critical factor, requiring compatibility with the concrete mixers in use or purchasing a concrete mixer with pump designed to complement a specific mixer.

Selecting the Right Concrete Pump

Choosing the right pump for your business involves considering three key factors. Firstly, opt for a manufacturer renowned for producing concrete pumps of various sizes and styles. Secondly, ensure the selected pump has the power to deliver concrete, even when pumping at steep angles. Finally, factor in the cost, seeking a concrete pump for sale in Saudi Arabia from a company offering competitive pricing and potential discounts. The ideal concrete pump results from a balance of these factors, tailored to suit your business needs.

Identifying Quality in a Concrete Pump

While scrutinizing specifications is crucial, the true measure of a concrete pump’s quality lies in its performance. Choosing a pump from a reputable manufacturer in the concrete equipment industry ensures reliability. The cost of equipment often reflects its quality, but there are companies known for producing affordable yet durable concrete pumping equipment.

Contact multiple manufacturers, request estimates, and conduct thorough research to find the right equipment for your business. Pumps employing the twin-piston design are indicative of long-term durability and substantial power. Quality may come at a higher cement pump price, but diligent research will lead you to affordable, well-designed concrete mixer with pump. Employing only the best equipment is imperative for maximizing productivity in your concrete-related business.

your comment

your comment

-

Enter the realm of the single-cylinder cone crusher—a marvel in simplicity and efficiency. Explore the intricacies of its design and functionality, dissecting the singular power it brings to the crushing arena.

In the critical examination of the single-cylinder cone crusher, unmask both its strengths and limitations. Navigate through the efficiency landscape and understand where this singular powerhouse shines and where it might stumble.

Navigating the Multi-Cylinder Cone Crusher Terrain

The Multifaceted Approach

1. Multi-Cylinder Dynamics: The Symphony of Power

Shift gears to the multi-cylinder cone crusher—a symphony of power and precision. Delve into the multifaceted dynamics that orchestrate its crushing prowess, exploring how multiple cylinders synchronize to achieve unparalleled efficiency.

2. Dissecting Advantages and Potential Drawbacks: A Thoughtful Examination

In a thoughtful examination, dissect the advantages and potential drawbacks of the multi-cylinder cone rock crusher. Balance the scales, understanding where its complexity elevates performance and where it might introduce challenges.

Strategic Selection: Factors for Choosing the Right Crusher

The Decision Matrix

1. Operational Demands: Matching Crusher to Purpose

In the decision matrix of crusher selection, prioritize operational demands. Assess the specific purpose and requirements, ensuring a seamless match between the crusher—be it single or multi-cylinder—and the tasks at hand.

2. Future-Proofing Investments: Considering Long-Term Viability

Beyond the immediate, consider the long-term viability of your investment. Explore how each crusher aligns with future needs, ensuring your choice stands the test of time and technological advancements.

In the intricate landscape of cone crusher choices, the decision between single-cylinder and multi-cylinder options demands thoughtful consideration. Unveil the singular power of the single-cylinder cone stone crusher, navigate the symphony of the multi-cylinder, and strategically select based on operational demands and long-term viability. In the realm of crushers, choosing wisely is the key to unlocking efficient and enduring crushing solutions.

your comment

your comment

-

A vital mobile concrete mixer that you might like to have for your business is called a self loading concrete mixer. This basically means that it can aggregate itself. All of the materials might be loaded automatically, then everything will be mixed while not having to concern yourself with a thing. Once this is done, since it a part of an automobile, it can be transported to wherever the concrete is necessary, mixing the materials mainly because it goes along. They are probably one of the more recognizable bits of construction equipment that individuals see going later on every single day. For those who have a business that must expand, and you must purchase one of these simple concrete mixers, there are ways to get phenomenal deals.

Why Would Your Business Have To Have One?

Like a company continues to grow, it is actually extremely important to improve your efficiency and speed. If you have a self loading concrete mixer, it can load every one of the aggregate material, and mix all the cement and water together inside the perfect combination. What tends to happen with concrete is it can set very quickly. That’s why the rotating from where the content is added continue to spin all the way before you reach your destination. It can actually carry on and spin when you are pouring it out. It can have been extendable funnel or ramp down in which the concrete is going to be poured. These are movable and adjustable, helping you to position it just where the concrete needs to be poured.

Locating Businesses That Sell These At Discount Prices

Prior to buying one of these brilliant units, it is essential to check out all of your alternatives. You might purchase a used one who is in your town from a construction company, or you might have a brand-another one that will last three times for as long. Whenever you order overseas, and possess it shipped to the location, you can actually save a considerable amount of money when you are employing this strategy. The combination of your total price of the self loading concrete mixer combined with the shipping fees are frequently lower than what you could get domestically. Lots of people purchase nearly all their construction equipment for industrial and commercial projects from companies like China because of how low the charge is really. View more info here: https://concretemixerwithpump.com/self-loading-concrete-mixer-uganda/.

Always Compare Prior To Buying

The comparison that you have to do on these products starts off with checking out the tank body and main structure. Make certain that it is made of the lowest alloy steel, one who will have excellent wear resistance. It ought to have got a hydraulic system that can provide reliable performance, and capability to do its job. It should possess a reliable water and aggregate supply system, and you also need to make sure that dual helical blades are throughout the mixing drum. If all of this checks out, and you may select one that may be with an extremely good deal, you should place your order on the web.

Whether you must have one of these simple self loading concrete mixer for sale in Malaysia, or even an entire number of them, the only method that you will be able to economize when you purchase them is always to investigate. It can usually take you a few momemts to find several firms that offer great deals, leading you to the lowest cost concrete mixers which can be self-loading and brand-new.

your comment

your comment

-

Crushed stone, a cornerstone in construction, necessitates an efficient process for its transportation and storage post-production. The methodology behind these crucial steps in the stone processing journey demands precision and practicality.

Crushed Stone Transportation

Conveyor Belt Systems

In the domain of stone processing logistics, conveyor belt systems emerge as the backbone for transporting crushed stone from production to storage. These robust systems employ durable belts driven by motors, efficiently moving vast quantities of crushed stone over distances. The automated nature of conveyor belt systems ensures a continuous and controlled flow of material, minimizing manual intervention and enhancing operational efficiency.

Truck Hauling Methods

Supplementing the precision of conveyor belt systems, truck hauling methods play a pivotal role in transporting crushed stone, especially in scenarios where direct conveyor access is impractical. Specialized dump trucks equipped with high-capacity containers navigate the terrain between the stone crushing plant and storage areas. The efficiency of these hauling methods lies in their adaptability to diverse site conditions, providing a flexible solution for stone transportation.

Crushed Stone Storage

Stockpiling in Designated Areas

Once transported, efficient stockpiling of crushed stone becomes paramount. Designated areas within the stone yard or storage facility are strategically planned for this purpose. Bulldozers and loaders arrange the crushed stone into neat, organized stockpiles. This systematic approach not only facilitates easy retrieval based on stone specifications but also ensures an orderly visual presentation of the stored material. View plant details here: https://aimixcrusherplant.com/combined-mobile-crusher-plants/.

Utilization of Bins and Silos

For a more controlled storage environment, stone crushing plants often incorporate bins and silos into their storage infrastructure. Bins, typically open-topped containers, provide accessible storage for smaller quantities of crushed stone. Silos, on the other hand, are enclosed structures designed for larger capacities, offering protection against environmental elements. These storage solutions optimize space utilization and safeguard the crushed stone from external factors, ensuring the material's quality remains intact.

Conclusion

In conclusion, the transportation and storage of crushed stone from a stone crushing plant for sale epitomize the intersection of engineering precision and practical logistics. From the mechanized efficiency of conveyor belt systems and truck hauling methods to the organized stockpiling in designated areas and the controlled environment of bins and silos, each step in this process is a testament to the meticulous handling of a fundamental construction material.

your comment

your comment

-

A concrete mixer truck that loads on its own is vital if you are running a business. You would like to ensure the project will probably just do it seamlessly and this won't happen unless there is a solution such as this. Plenty of businesses still visit a dip with their profit margins mainly because they don't have a great mixing truck on their hands.

Which are the reasons that you are going to want to start using a high-quality self loading concrete mixer truck?

It's planning to come down to a variety of benefits that matter and here are some of the most important ones to be aware of.

Efficiency

The efficiency that you are going to see with something similar to this is going to be a game-changer and it's gonna matter when it's time to find a good fit. A great deal of businesses don't think of this and that is why their mixing processes don't exercise as intended.

A great concrete mixer truck is going to allow you to do items that are easier to manage within the long term. Keep things simple, therefore you have the right path and it all works out as planned.

Speed

The pace in which you are likely to use the concrete mixer truck is the thing that will matter. Imagine having a large project and you also need concrete the instant you can get your hands on it. It is a common situation and also the goal always must be to target speed.

Should you be not focused on speed, you will be considered a step behind. By using a concrete mixer truck you will know the quality will likely be there and it will be easy to take care of the speed-related demands of the upcoming project.

Simplicity

Operating a concrete mixer truck is easy and that is certainly something you are going to value. You don't need a situation where things aren't progressing so you are increasingly being held back from the equipment inside your possession. This is the reason a growing number of companies are looking for a way to beef up their setup and build towards something that is going to increase the value of their business.

This is a must for anybody that would like to make sure they are getting a great deal. If you are in this boat, consider finding a good self loading concrete mixer in Indonesia that can consistently work effectively when you input it to work with.

The main reason a lot of people enjoy concrete mixer trucks is related to how quickly they carry on loads of concrete which needs to be mixed. Other solutions are going to take a large amount of some time and which can be cumbersome eventually. Using this, you are going to be aware of quality will likely be there and it's gonna shine through when it's time for you to yield results.

An effective self-loading mixing truck is essential and has to be the basis of everything you are doing.

your comment

your comment

-

Crushers are essential machines for breaking down large rocks into construction-appropriate sizes, providing materials like sand, gravel, and smaller rocks for diverse construction purposes.

Jaw Crusher

Jaw crushers are the most common stone crushers, exerting compressive force until material breaks. They offer adjustable sizing and are ideal for large-scale projects, crafted with durable materials like steel and cast iron.

Cone Crusher

Cone crushers consist of a cone, crushing chamber, and operational mechanism, breaking stones through squeezing. Eccentrically rod-supported, the cone crusher for sale features a wear-resistant mantle for efficiency. Suitable for large-scale crushing, it reliably breaks mid-hard or sturdy materials.

Gyratory Crusher

Gyratory crushers operate similarly to jaw crushers, with a cone-shaped head and concave surface. Manganese liners ensure smooth operation. Crushing occurs as the mantle line and concave liners meet, gyrating around the central vertical axis. Suitable for various stones, the broken material moves for further processing.

These are three of the best stone crusher types, each with unique capabilities. Many others with different features exist, so evaluate your needs to choose the most suitable one for your requirements.

your comment

your comment

-

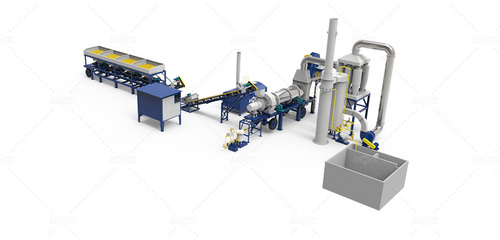

Crushing plants stand as stalwarts in project development, acting as robust machinery designed to break down materials efficiently. From extracting minerals to recycling concrete, their applications are as diverse as the materials they handle. Understanding the fundamentals of these plants lays the foundation for successful project execution.

Definition and Functionality

Crushing plants are complex assemblies of machinery designed to crush and screen various materials into different sizes. They play a pivotal role in industries such as mining, construction, and recycling. Primary components include crushers, conveyors, and screening units, working seamlessly to transform raw materials into usable aggregates.

Diverse Applications in Project Development

The versatility of crushing plants makes them indispensable across an array of projects. Whether it's extracting minerals from mines, preparing materials for construction, or recycling concrete debris, these plants offer a crucial link in the project development chain. Recognizing their adaptability is key to harnessing their full potential.

Navigating the Landscape of Blooming Deals

Understanding Economic Dynamics

In the realm of crushing plants, economic forces exert a significant influence on the deals available in the market. A nuanced understanding of market trends and a keen eye on global factors can empower project managers to make informed decisions and secure advantageous deals.

Market Trends and Demand Analysis

Staying abreast of market trends ensures that project managers can anticipate fluctuations in the prices of crushing plants. Analyzing demand patterns helps in identifying opportune moments to make purchases, aligning with market dynamics for cost-effectiveness.

Impact of Global Factors on Crushing Plant Prices

Global economic shifts, geopolitical events, and technological advancements can influence the prices of mobile stone crushing plant. Recognizing these external factors allows project managers to navigate the market strategically, capitalizing on blooming deals during favorable conditions.

Types of Deals in the Crushing Plant Sphere

Navigating the market for crushing plants involves exploring diverse deal structures. From auctions and discounts to seasonal promotions, understanding the types of deals available is essential for project managers seeking to optimize their budgets.

Auctions, Discounts, and Seasonal Promotions

Auctions provide a dynamic platform for securing crushing plants at competitive prices. Discounts and seasonal promotions, on the other hand, offer windows of opportunity for cost-efficient acquisitions. Project managers should be adept at identifying these diverse deal structures to make informed choices aligned with project timelines and budgetary constraints.

Evaluating Long-Term Contracts for Cost Efficiency

Long-term contracts can provide stability and cost-efficiency in procuring crushing plants. Assessing the feasibility of such contracts involves a comprehensive evaluation of projected project timelines, material requirements, and budget constraints. Strategic planning ensures that long-term commitments align with project goals.

Strategic Implementation for Project Elevation

Selecting the Right Crushing Plant for Your Project

The success of any project hinges on selecting the right crushing plant tailored to specific requirements. Project managers must navigate through a myriad of options, considering project specifications, environmental considerations, and operational needs.

Assessing Project Requirements and Specifications

Understanding the unique requirements of a project is paramount in selecting an appropriate crushing plant. Factors such as material type, size specifications, and production capacity play a crucial role. A meticulous assessment ensures that the chosen plant aligns seamlessly with project goals. More useful info, check this page: https://aimixcrusherplant.com/portable-crusher-plant/

Considering Environmental and Operational Factors

Environmental considerations, such as emission controls and noise regulations, are integral aspects of project planning. Simultaneously, operational factors, including ease of maintenance and adaptability to site conditions, contribute to the sustainable and efficient functioning of the crushing plant. Balancing these considerations ensures a harmonious integration into the project environment.

Maximizing Blooming Deals for Optimal Project Outcomes

Negotiation Strategies for Cost-Effective Purchases

Effective negotiation is an art that project managers can master to secure the best deals on crushing plants. Understanding market dynamics, conducting thorough research, and skillful negotiation tactics contribute to achieving favorable terms. Project managers should approach negotiations with a comprehensive understanding of the plant's value and their budget constraints.

Leveraging Warranties and Maintenance Packages

Blooming deals extend beyond the initial purchase price. Savvy project managers recognize the value of warranties and maintenance packages offered by manufacturers. Leveraging these additional benefits enhances the long-term viability of the crushing plant, providing peace of mind and optimizing project outcomes.

In conclusion,

the realm of crushing plants offers a landscape of opportunities for project managers to elevate their projects. By unraveling the intricacies of crushing plant for sale functionality, navigating economic dynamics, and strategically implementing acquisitions, project managers can harness blooming deals

your comment

your comment

-

Welcome to the Quarry Kingdom, where rocks reign supreme, and the throne belongs to none other than the Crusher Plant Suppliers. In this stone-laden saga, we embark on a journey to unravel the secrets of their rule. Picture a realm where crushers roar, and suppliers don the crown of stone sovereignty. The stage is set for a quarry drama like no other. As we pull back the quarry curtain, the true stars emerge – the Sultans of Supply, the Crusher Plant Suppliers. These aren't just suppliers; they're rulers of the rocky realm. With their stone scepters and efficiency swords, they command a kingdom where rocks bow to their crushing might. Let the unveiling of the stone sultans commence!

Crushing Hegemony: The Rulebook of Crusher Plant Suppliers

A. Supply Sultan Strategies: Unearthly Efficiency

Ever wondered how the stone sultans maintain their hegemony? It's all about unearthly efficiency. The Supply Sultans have a rulebook written in stone, where every move is calculated, and every supply chain is finely tuned. Efficiency isn't just a virtue; it's a scepter they wield to crush the competition. Witness the dance of conveyor belts and the symphony of stone sorting – it's efficiency incarnate.

B. Quarry Queendoms: Breaking Down Supplier Sovereignty

Within the Quarry Kingdom, the Crusher Plant Suppliers establish their queendoms, where sovereignty is built on the foundation of robust machinery and unparalleled service. They break down the notion of supply limitations, creating a realm where rocks are sourced with the precision of surgical strikes. The queendoms of these sand crusher plant suppliers are not just places of business; they're epicenters of quarry authority.

The Coronation of Success: Impact of Crusher Plant Suppliers on the Quarry Realm

A. Rock Royalty: Suppliers' Influence on Quarry Dynamics

The impact of Crusher Plant Suppliers on quarry dynamics is nothing short of rock royalty. They influence not just the extraction process but the entire quarry ecosystem. Their machinery becomes the crown jewel, and their expertise shapes the very bedrock of success. It's a coronation where rocks become royalties, and the suppliers wield the scepter of influence.

B. The Quarry Chronicles: Tales of Supplier Triumphs

In the Quarry Chronicles, tales of supplier triumphs echo through the stone-laden corridors. Stories of increased productivity, reduced downtime, and elevated safety standards become the saga of the Quarry Kingdom. The Crusher Plant Suppliers aren't just rulers; they're authors of a quarry epic, where each chapter unfolds with a new triumph and every stone tells a tale of supplier success. In conclusion, the Quarry Kingdom stands as a testament to the rule of the Stone Sultans – the Crusher Plant Suppliers. Their efficiency is a scepter, and their machinery, a crown. As we close the quarry curtain on this saga, the stone sultans continue to rule, their influence echoing through the rocky realm, shaping the very foundations of quarry success.

your comment

your comment

-

As we wander down the asphalt-paved lanes of nostalgia, we find ourselves at the crossroads of innovation and tradition. The world of asphalt plants, once a domain of behemoth structures and grand machinery, is now witnessing the quiet but intriguing emergence of small portable asphalt plants. With a hint of wistfulness, let us explore whether these compact marvels are poised to take the market by storm.

I. The Evolving Landscape of Asphalt Plants

A brief stroll down memory lane in the world of asphalt plants

In the annals of history, one cannot help but marvel at the evolution of asphalt plants sale. We reminisce about the towering behemoths that stood as symbols of progress and construction. These giants paved the way for modern infrastructure. But the passage of time has ushered in changes, and technology has paved the path to miniaturization.Introducing the concept of small portable asphalt plants

The stars of our tale, small portable asphalt plants, are compact wonders that have quietly graced the industry. These miniaturized versions offer flexibility and mobility, carving a niche for themselves in the hearts of asphalt producers. They are the ‘David’ in a world of ‘Goliaths,’ and their presence is beginning to leave a lasting impression.

II. The Intriguing Advantages of Small Portable Asphalt Plants

Compact and agile: The charm of portability

The allure of these small portable plants lies in their nimbleness. They can be transported with ease, adapting to the requirements of various projects. Their mobility translates into savings in time and resources, making them an appealing choice for those looking to produce asphalt on the go.Environmental strides: Small plants with a big green heart

In an era when environmental consciousness is more than a passing trend, small portable asphalt plants are stepping up to the plate. Their smaller scale often results in lower emissions and reduced energy consumption. With a focus on sustainability, they are winning the hearts of those who desire greener infrastructure solutions. Get more information here:https://aimixasphaltplant.com/mini-asphalt-mixing-plant/.III. Navigating the Future: Challenges and Prospects

Potential roadblocks to the small portable asphalt plant revolution

While the journey of small portable asphalt plants has been promising, there are challenges ahead. Questions about production capacity and cost-effectiveness may cast a shadow over their ascension. However, innovation and adaptation are the cornerstones of progress, and these challenges may yet be surmounted.

The legacy of innovation: Why small may indeed be beautiful

In the world of asphalt, where tradition and innovation coexist, small portable asphalt plants are a testament to the enduring spirit of progress. As we ponder their future, we are reminded that change is a constant companion in the journey of industry. With innovation as their ally, small portable asphalt plants may indeed carve a memorable legacy.In conclusion, dear reader, the ascent of small portable asphalt plants in the market is a tale both nostalgic and forward-looking. Their compact charm and environmental promise evoke the nostalgia of the past while beckoning us toward a greener and more flexible future. As we watch their journey unfold, we stand on the precipice of a new era in the world of small portable asphalt plants.

your comment

your comment

-

Concrete mixers, often overshadowed by the structures they help build, play a pivotal role in the evolution of the Turkish construction industry. In understanding the hottest trends in concrete mixers, one must first grasp their significance in the broader context of construction. This article explores the transformative trends in Turkey's construction sector and the crucial role concrete mixers play in this paradigm shift.

Concrete mixers are the unsung heroes of any construction project, serving as the beating heart that amalgamates the building blocks of progress. They are the linchpin in the creation of durable, reliable structures, providing the necessary cohesion to the amalgamation of concrete and steel. In Turkey, a nation witnessing a construction boom, the role of concrete mixers in Turkey becomes even more pronounced.

Turkey's construction industry is undergoing a metamorphosis, with a shift towards innovation, efficiency, and sustainability. Concrete mixers, once seen merely as utilitarian machinery, are now at the forefront of technological and design advancements. Understanding the emerging trends in the Turkish construction scene requires a closer look at the evolution of concrete mixers.

Exploring Innovative Concrete Mixer Designs:

Integration of Traditional Turkish Craftsmanship

In a fascinating fusion of tradition and modernity, Turkish concrete mixers showcase an integration of traditional craftsmanship. The synergy between time-honored techniques and contemporary engineering elevates the design of these mixers to an art form. This section unravels the nuances of how Turkish manufacturers infuse a sense of cultural identity into the very design of the concrete mixers.

Incorporating Advanced Technology for Efficiency

Efficiency is the cornerstone of any construction endeavor, and Turkish concrete mixers are embracing advanced technology to redefine efficiency standards. From automated mixing processes to real-time monitoring systems, this section explores the technological innovations that propel Turkish concrete mixers into a new era of precision and effectiveness.

Aesthetic Considerations in Concrete Mixer Design

Beyond functionality, there is a growing emphasis on aesthetics in concrete mixer design. The once overlooked machinery is now a canvas for artistic expression. This section explores how Turkish concrete mixers are not just tools but visual statements that contribute to the overall aesthetic appeal of construction sites, reflecting a nuanced blend of form and function. Find more info about mixer here: https://concretemixerwithpump.com/self-loading-concrete-mixer-for-sale-in-nigeria/.

The Role of Concrete Mixers in Sustainable Construction:

Material Efficiency and Waste Reduction

Sustainability in construction starts with responsible material usage. Turkish concrete mixers are increasingly geared towards material efficiency, minimizing waste and optimizing the use of resources. This section sheds light on the innovative approaches within the Turkish construction industry to reduce the ecological footprint of concrete mixing.

Energy-Efficient Concrete Mixing Processes

Energy efficiency is a paramount concern in contemporary construction. Turkish concrete mixers are aligning with this ethos by incorporating energy-efficient processes. From intelligent power management systems to eco-friendly fuel alternatives, this section elucidates how these mixers are contributing to a more sustainable and energy-conscious construction landscape.

Contribution to Green Building Standards

Green building standards are gaining prominence globally, and Turkey is not lagging. Concrete mixers play a vital role in meeting these standards by adopting practices that align with environmentally friendly construction norms. This section discusses how Turkish concrete mixers are instrumental in the construction of buildings that adhere to green certifications, fostering a more sustainable built environment.

In conclusion, the hottest concrete mixers in Turkey are not merely machines; they are the vanguards of a construction revolution. As they seamlessly integrate tradition with innovation, efficiency with aesthetics, and functionality with sustainability, the self loading concrete mixer stands as a testament to Turkey's commitment to shaping a future where progress harmonizes with environmental responsibility. For more information, visit .

your comment

your comment

-

Concrete mixers, often overshadowed by the structures they help build, play a pivotal role in the evolution of the Turkish construction industry. In understanding the hottest trends in concrete mixers, one must first grasp their significance in the broader context of construction. This article explores the transformative trends in Turkey's construction sector and the crucial role concrete mixers play in this paradigm shift.

Concrete mixers are the unsung heroes of any construction project, serving as the beating heart that amalgamates the building blocks of progress. They are the linchpin in the creation of durable, reliable structures, providing the necessary cohesion to the amalgamation of concrete and steel. In Turkey, a nation witnessing a construction boom, the role of concrete mixers in Turkey becomes even more pronounced.

Turkey's construction industry is undergoing a metamorphosis, with a shift towards innovation, efficiency, and sustainability. Concrete mixers, once seen merely as utilitarian machinery, are now at the forefront of technological and design advancements. Understanding the emerging trends in the Turkish construction scene requires a closer look at the evolution of concrete mixers.

As the global community embraces sustainable practices, Turkey is no exception. Concrete mixers, traditionally associated with resource-intensive processes, are now undergoing a green revolution. This section delves into the ways in which the Turkish construction industry is transitioning towards more sustainable concrete mixing practices, aligning with contemporary environmental standards.

Exploring Innovative Concrete Mixer Designs:

Integration of Traditional Turkish Craftsmanship

In a fascinating fusion of tradition and modernity, Turkish concrete mixers showcase an integration of traditional craftsmanship. The synergy between time-honored techniques and contemporary engineering elevates the design of these mixers to an art form. This section unravels the nuances of how Turkish manufacturers infuse a sense of cultural identity into the very design of the concrete mixers.

Incorporating Advanced Technology for Efficiency

Efficiency is the cornerstone of any construction endeavor, and Turkish concrete mixers are embracing advanced technology to redefine efficiency standards. From automated mixing processes to real-time monitoring systems, this section explores the technological innovations that propel Turkish concrete mixers into a new era of precision and effectiveness.

Aesthetic Considerations in Concrete Mixer Design

Beyond functionality, there is a growing emphasis on aesthetics in concrete mixer design. The once overlooked machinery is now a canvas for artistic expression. This section explores how Turkish concrete mixers are not just tools but visual statements that contribute to the overall aesthetic appeal of construction sites, reflecting a nuanced blend of form and function.

The Role of Concrete Mixers in Sustainable Construction:

Material Efficiency and Waste Reduction

Sustainability in construction starts with responsible material usage. Turkish concrete mixers are increasingly geared towards material efficiency, minimizing waste and optimizing the use of resources. This section sheds light on the innovative approaches within the Turkish construction industry to reduce the ecological footprint of concrete mixing.

Energy-Efficient Concrete Mixing Processes

Energy efficiency is a paramount concern in contemporary construction. Turkish concrete mixers are aligning with this ethos by incorporating energy-efficient processes. From intelligent power management systems to eco-friendly fuel alternatives, this section elucidates how these mixers are contributing to a more sustainable and energy-conscious construction landscape.

Contribution to Green Building Standards

Green building standards are gaining prominence globally, and Turkey is not lagging. Concrete mixers play a vital role in meeting these standards by adopting practices that align with environmentally friendly construction norms. This section discusses how Turkish concrete mixers are instrumental in the construction of buildings that adhere to green certifications, fostering a more sustainable built environment.

In conclusion, the hottest concrete mixers in Turkey are not merely machines; they are the vanguards of a construction revolution. As they seamlessly integrate tradition with innovation, efficiency with aesthetics, and functionality with sustainability, these self loading mixers stand as a testament to Turkey's commitment to shaping a future where progress harmonizes with environmental responsibility.

your comment

your comment

-

Setting up an industrial venture, particularly a small concrete plant, involves a myriad of initial costs. This article delves into the financial aspects of establishing a small concrete plant, exploring the various expenses associated with the setup process and providing insights on how to mitigate these costs.

The Initial Costs

The primary consideration in setting up a small concrete plant is the cost of the plant itself. Ranging from five to seven figures, this investment depends on the complexity and productivity of the small concrete batch plant. Additionally, shipping costs can significantly contribute to the financial outlay, especially for larger facilities. Acquiring suitable land for the plant is another expense, along with ensuring the infrastructure for water, electrical, and gas systems is in place, tailored to the specific requirements of the chosen concrete batching plant.

Minimizing Setup Costs

To alleviate the upfront financial burden, obtaining multiple quotes from various businesses is crucial. Diverse companies offer varying prices for small concrete plants, and obtaining estimates allows for an informed decision. Bidding for individual tasks, such as electrical and gas line installations, enables cost savings. Opting for the lowest bid in these areas can translate to substantial financial benefits, minimizing the overall setup expenditure.

Navigating Initial Costs Effectively

Not every business undertaking the setup of a small concrete plant has to bear all the initial costs mentioned. Existing infrastructure, such as previously established concrete batching plants, can reduce certain expenses. Additionally, if a business already employs professionals like plumbers, electricians, or gas line experts, their services can be repurposed for setting up the ready mix plant. Shifting their efforts towards the new project can streamline the process and potentially cut down costs.

Conclusion

The journey of purchasing and installing a small concrete plant unfolds as a significant financial commitment. Often, companies specializing in entire concrete batching plants demand substantial sums. However, with meticulous evaluation, obtaining multiple quotes, and strategic bidding for individual tasks, businesses can navigate the setup costs more effectively. Recognizing existing resources and infrastructure can further contribute to financial efficiency. In the realm of industrial ventures, establishing a small concrete plant requires not just financial investment but also shrewd decision-making to optimize resources and cut unnecessary costs. Learn more about plant here: https://aimixgroup.ph/concrete-batching-plant-price/.

your comment

your comment

-

In the world of rock crushing, finding ways to save costs without compromising quality is a paramount goal for businesses. Whether you're a small-scale mine owner or operating a large quarry, reducing rock crusher costs can significantly impact your bottom line. This article will guide you through effective strategies to score big savings on rock crusher costs, allowing you to optimize your operations and maximize profitability.

Strategies for Saving on Rock Crusher Costs

To achieve substantial cost savings when purchasing a rock crusher, consider implementing the following strategies:

Research and Compare Prices

Before making a purchase, invest time in thorough research and compare prices from multiple suppliers. The market is highly competitive, and prices can vary significantly. By gathering quotes and negotiating with suppliers, you can secure the best deal possible. Don't hesitate to leverage your knowledge and competition to drive prices down. Remember, the goal is to get the most value for your investment without compromising quality or performance. Find more info here: https://aimixgroup.ph/stone-crusher-plant/.

Consider Used or Refurbished Options

Another effective strategy to save on rock crusher costs is to explore used or refurbished options. Many reputable suppliers offer pre-owned or refurbished rock crushers that have been inspected, repaired, and restored to excellent working condition. These machines often come at a fraction of the cost of a brand-new crusher while maintaining comparable performance. Don't overlook this opportunity to score significant savings without sacrificing functionality.

Maximizing Efficiency to Reduce Operating Costs

Beyond initial acquisition costs, optimizing the efficiency of your rock crusher operations can lead to substantial long-term savings.

your comment

your comment

-

In the industry of construction and mining, the search for the perfect river stone crusher is akin to a treasure hunt. To uncover the hidden gems of affordability and quality, one must embark on a journey through the Philippines' market. In this article, we'll dive into the quest of finding the best deals on these essential machines.

Exploring the Philippines Market

Local Suppliers and Dealers

The Philippines is rich in natural resources, and river stones are no exception. To start your search, consider local suppliers and dealers:

-

Brick-and-Mortar Stores: Pay a visit to local heavy equipment stores and dealers. They often offer a hands-on experience and the opportunity to inspect the tractor rock crusher in person.

-

Networking and Recommendations: Connect with fellow industry professionals and gather recommendations. They might point you to reliable local suppliers.

Online Platforms and Auctions

In this digital age, the world of commerce has expanded into cyberspace, and river stone crushers are no exception. Explore online options:

-

E-commerce Platforms: Websites like Lazada and Shopee often host sellers offering a variety of river stone crushers.

-

Auctions and Bidding Sites: Keep an eye on auction websites, where you might stumble upon competitive deals and bidding wars.

Navigating the Purchase

Quality and Features

When searching for the best deal, it's not just about the price; it's about the quality and features of the river stone crusher:

-

Performance Specifications: Consider the crushing capacity, power source, and output quality. A crusher with the right specs can save you money and time in the long run.

-

Durability and Maintenance: Assess the build quality and ease of maintenance. A durable machine with accessible maintenance points can be a wise investment.

-

Price Negotiation and Shipping Options

Now comes the thrilling part—negotiating the deal and getting your crusher to your location:

-

Price Negotiation: Don't be afraid to haggle. Many sellers are open to negotiations, and you might secure a better deal than the initial price.

-

Shipping and Logistics: Evaluate the shipping options, costs, and delivery times. Some suppliers might offer convenient shipping solutions. Find more information here: https://aimixgroup.ph/aggregate-crusher-plant/.

In conclusion, the search for the best deal on a river stone crusher in the Philippines is an adventure worth embarking on. By exploring local suppliers and dealers, as well as tapping into the digital marketplace, you can uncover competitive offers. Remember, it's not just about the price; it's about the perfect combination of quality, features, and affordability that will make your investment truly valuable. So, gear up for your quest and equip your operations with the best in the business.

your comment

your comment

-

-

The world of construction and mining is witnessing a paradigm shift, with mobile crusher plants emerging as the favored choice among industry professionals. These versatile machines have, in recent years, stolen the spotlight for their unmatched advantages. In this article, we delve into why mobile crusher plants have earned such a robust reputation, dissecting their key benefits, diverse applications, and the technological advancements that have propelled them into the limelight. I. Introduction The Evolution of Mobile Crusher Plants Mobile crusher plants represent the evolutionary pinnacle of material processing equipment. It's crucial to understand their journey from their humble beginnings to the advanced machinery we know today. The Growing Popularity The surge in popularity of mobile crusher plants has been impossible to ignore. Let's explore the factors that have contributed to their widespread adoption and the changing dynamics of industries they serve.

Advantages of Mobile Crusher Plants Mobility and Flexibility

One of the standout features of mobile crusher plants is their unmatched mobility. These machines can be easily relocated from one job site to another, providing unparalleled flexibility and agility for various applications. Cost-Efficiency and Environmental Benefits In an era where sustainability is paramount, mobile cone crusher for sale garnered praise for their cost-efficiency and positive environmental impact. We will delve into the financial savings and eco-friendly aspects that make them stand out.

Applications and Industries

Construction and Demolition

From crushing concrete debris to recycling asphalt, mobile crusher plants play a pivotal role in the construction and demolition sector. We will uncover their contributions to these vital industries.

Mining and Quarrying

In the mining and quarrying sectors, where efficiency and productivity are imperative, mobile crusher plants have revolutionized the extraction and processing of minerals. We will explore how they have become indispensable in these domains. You can check more info about mobile crusher here: https://aimixgroup.ph/mobile-crusher-plant/.

Technological Advancements

Integration of Automation

Modern mobile crusher plants have embraced cutting-edge automation, enhancing efficiency and safety. We will dissect the integration of automation in these machines and how it impacts daily operations.

Enhanced Performance and Safety Features

The quest for perfection has led to remarkable advancements in the performance and safety features of mobile crusher plants. We'll take a closer look at these enhancements and their significance in the industry. In conclusion, the surging popularity of mobile stone crusher for sale is not by chance but a result of their unparalleled advantages, versatile applications, and continuous technological enhancements. As these machines continue to evolve, they are expected to remain at the forefront of the construction and mining industries, catering to the ever-growing demands of the modern world.

your comment

your comment

-

Are you considering investing in jaw stone crushers? If you think you might want to purchase equipment like this, you'll want to find out more about what these crushing machines offer. These are a few interesting things everyone should know about crushing equipment.

Some Jaw Crushers Are Portable

If you're going to be crushing stones at job sites, you'll be pleased to know that it's possible to invest in portable equipment. There are crushers that are specifically designed to be transported from one site to another. With equipment like this, you can save time and improve efficiency.

Portable equipment is very popular right now, which means you should be able to find a lot of different options on the market. Buying portable crusher could cost you more initially, but over time, it's likely that it will save you money. Being able to complete essential tasks on the job site can reduce your costs.

Not All Stone Crushers Have The Same Capabilities

What a stone crusher is capable of will vary greatly based on the type of machine that you buy. There are machines that are able to break down even very large rocks, but there are also machines that can only handle rocks that are on the smaller side. Some machines can only handle softer types of rock, like limestone. Learn more about stone crusher here: https://aimixgroup.ph/stone-crusher-plant/

Because of this, it's important to learn more about any machine that you might want to buy. If you are familiar with the capabilities of a machine, you'll be able to see if that machine is a smart investment for you.

Jaw Crushers Require Regular Maintenance

It's important to properly maintain a jaw crusher. A stone crushing machine can easily be damaged over time. If a machine isn't well maintained, it might have a shortened lifespan.

What kinds of maintenance do these machines usually need? One of the most common requirements is that these machines need to be properly cleaned between uses. It's also a wise idea to read the manual that came with the machine so that you can learn more about how to care for the machine.

Jaw Crushers Come In Many Sizes

The size of this sort of equipment can vary greatly based on the type of machine that you choose to buy. When shopping online, it's important to look at the product descriptions so that you can see how large or small the equipment really is.

Smaller stone crushers can be useful when crushing rocks of a smaller size. Smaller equipment also tends to be more portable. However, there are also many crushing machines that are much larger in size and scale. Always look at the dimensions of a product so that you can see how large it really is.

There are a number of interesting things to consider before buying jaw stone crushers. Since this sort of equipment can be expensive, it's a mistake to make a purchase without learning more. These functional machines can be very useful, but you'll still want to take a closer look at them before spending money.

your comment

your comment

-

Crushers are specialized machines designed to break down raw materials and reduce their size for various applications. While stationary crushers have been the norm, the popularity of mobile jaw crushers is on the rise. These crushers offer more than just convenience for individuals working across multiple job sites; they bring a range of additional benefits.

Unmatched Versatility with Portable Crushers

The exceptional flexibility offered by a mobile crusher stands as a compelling reason to opt for this equipment. Despite their impressive functionality, these machines are designed to be lightweight and equipped with wheels, ensuring easy mobility.

With a portable crusher at your disposal, you gain the ability to tackle a wider array of tasks. Concerns about accessing the necessary crushing equipment diminish, allowing you to focus more on completing essential tasks efficiently.

Cost Savings Enabled by Mobile Crushers

While purchasing a crusher constitutes an investment, the returns are multi-fold. On-site crushing minimizes material transportation costs, leading to substantial savings over time. As your operations continue, these savings will grow exponentially.

Selecting the right equipment is pivotal for your business. Given that material transport expenses can be significant, exploring ways to mitigate these costs is prudent.

Efficiency in Setup and Deployment

Larger jaw crushers come with logistical challenges during transportation. Disassembly before transit and reassembly on-site can consume valuable time.

In contrast, a mobile crusher eliminates these concerns. Transporting the machine becomes a hassle-free process, and there's no need for setup upon arrival. You can immediately put the stone crusher to work, optimizing productivity from the get-go.

Tailored Crusher Configurations to Suit Your Needs

A mobile crusher not only offers versatility but also customization options. You can select a crusher that aligns with your production goals, streamlining the process. The array of flexible configuration choices ensures smoother project execution.

Contrary to common belief, portable tools aren't limiting. In fact, they often offer expanded possibilities. Mobile crushers, despite their compact nature, can yield results comparable to larger crushing equipment, provided the appropriate configurations are in place.

Making an Informed Purchase

If the idea of a mobile jaw crusher resonates with your needs, your first step should be to locate a reputable vendor specializing in portable crushers. Once you've identified a trustworthy supplier, you can delve into various models and select the mobile crushing plant that best aligns with your requirements. This proactive approach ensures you invest in equipment that optimally supports your operations.

your comment

your comment

-

Are you wondering precisely what the average asphalt mixing plant price is? The reality is that the cost is determined by a multitude of factors, including plant configuration, capacity (30t/h, 100t/h, 250t/h, etc.) and plant type (hot recycling plant, mobile, drum mix, batch mixing, etc.). The price will mainly be dependant on the core requirements of your own project. Obviously, selecting the best manufacturer is also necessary for taking advantage of one of the most competitive prices. To get asphalt mixing plant price quotes from different suppliers, you have to be capable to clearly state your unique requirements.

Asphalt Mixing Plant Type

With so many different types of mixing plants available for purchase, for example portable asphalt plants, hot mix plants, stationary continuous asphalt plants plus more, buyer research is key. You should look into the advantages and drawbacks of every type of plant when it comes to your asphalt manufacturing project. The price difference between different plant types is likewise quite high. A stationary asphalt plant for sale, as an example, could cost more than tens times as much as a mini portable asphalt batch mix plant.

Hot Mix Plant Capacity

Choosing an asphalt mixing plant with sufficient capacity (hourly asphalt production output) for your needs is essential. You don't want to invest in an undersized plant only to need to change it out using a larger capacity model. The capacity of several asphalt mixing plant is usually quoted in tons an hour, but drum mix plants often also provide the mixing drum sizes listed. When you are unclear how you can determine your required plant capacity, be sure you talk to a top-rated asphalt plant supplier to talk about your project. The supplier will be able to allow you to choose the perfect solution for your personal asphalt manufacturing needs. Learn more info here: https://aimixasphaltplant.com/small-portable-asphalt-mixing-plant/

Asphalt Mixing Plant Configurations

There are various design options open to you in relation to choosing an asphalt mixing plant configurations. A number of the things to look at include how big meshes for vibrating screen, attached bitumen tank size, fuel tank size, finished mixture temporary storage facilities, baghouse dust collector quantities, aggregate hopper sizes plus much more. Take into consideration which make of burner you want to buy, along with speed reducer and electrical component manufacturers. The layout of your own asphalt mixing plant and your choice of components will have an impact on the total expense of any project.

Asphalt Plant Prices

If you are planning to purchase your asphalt manufacturing plant from an overseas supplier, there another asphalt plant price terms that you have to understand, including ex-factory price, FOB price, CIF price, and dutiable value. CFI means "Cost, Insurance and Freight" which is typically paid by the owner. It refers to the price of manufacturing, transporting and insuring goods until they reach the buyer's destination port. The dutiable value is a useful towards the total price by customs to recover tariffs on all imported and exported goods. Don't be concerned about understanding every one of the import taxes and charges, as overseas suppliers gives you a simple breakdown of all the costs included in your asphalt mixing plant price quote.

your comment

your comment

-

An asphalt plant plays a tremendous role in producing various materials, including asphalt, coated road stones, macadam, or asphalt concrete. All of these merchandise is applicable in varying projects because of their composition and durability. These items' production uses certain raw materials like aggregates, fillers, bitumen, and sand. The device can be purchased in varying models based on the type of needs a site could possibly be having. If you plan to get one, you must consider factors like size, models, and functionality levels. However, there is a question which includes always posed as a challenge to clients. Simply how much does asphalt plant cost? The pricing for this particular device varies widely, and the chance of getting overwhelmed is high.

Before you even start evaluating the figures, you must realise just how much this machine's price affects its performance. The design of the devices determines the pricing quotations. Technologies have paved how for inventing different variations to match any unique needs how the market has. The commonly used models consist of batch mix, drum mix plant, and recycling plants for mixed mixtures. The batch mix and drum versions can either are available in stationary or mobile designs. The pricing factor varies too, according to this feature. The disparity is vast because the sizing is another matter to take into consideration. While making choices, it is crucial to have in-depth understanding of your business needs. Take time and evaluate your market in terms of size and the demand you have. In this way, it will be easier to ascertain the velocity of output which will complement your requirements. The device by using a higher capacity and excellence of production is always expensive compared to the small designs. To obtain accurate information, you can expect to require the aid of a professional.

Lastly is definitely the configuration and requirements that you require. Exactly how much does asphalt plant cost determines the level of tasks it can execute? As an illustration, essential accessories like aggregate hopper come in different numbers depending on any project. The better you want, the greater number of the cash you have to spend. Other items just like the mesh size on the vibrating screen, the mode of your cabin, whether permanent or temporary, quantity of dust collectors, and also other electrical elements, and others. Although they could seem insignificant, assembling an asphalt plant until it gets operational requires much knowledge.

Nevertheless, manufacturing companies understand the demand for customers along with their mission to get devices at cheap prices. The owner will charge you depending on the sort of agreement which you choose. A machine's dutiable value signifies the amount imposed by customs. In situations your location shipping, the entire price gets dependant on the businesses. Another type is the free onboard price. With this contract, the vendor assumes every one of the shipping costs, and in the event of any risks, they are liable. In case the options don't seem convenient to suit your needs, you may speak with the vendor about your concern. In the event of any uncertainties, it is prudent to request for assistance instead of going to the venture blindly. Learn more info here: https://aimixasphaltplant.com/

your comment

your comment

-

You might have been spending less for a long period because you would like to purchase a mobile asphalt mixing plant. And you will have saved enough money now. But usually do not rush to buy a mobile asphalt mixing plant. It is possible to get some things wrong, specifically if you are buying the plant the first time. You must select the right mobile asphalt mixing plant.

There are numerous benefits for selecting the most appropriate mobile asphalt mixing plant. Choosing the proper mobile asphalt mixing plant saves time. It saves money. You can easily use and sustain. It lasts for some time. As well as the manufacturer selling they have the ideal customer satisfaction.

Here are benefits for selecting a right mobile asphalt mixing plant.

1. Saves Time

The proper mobile asphalt mixing plant saves time. How? These are effective. A number of people have used this asphalt production plant. They claim it performs the task perfectly. And it also needs a short period of time to generate asphalt. There is no need to wait patiently for a long time to get what you want.

Mobile asphalt mixing plant is light. So, you can easily transport. Will be your work site far? Usually do not worry. You can expect to reach there very quickly. This plant is just not like the big asphalt plants that happen to be hard to transport. So, if you have a mobile asphalt mixing plant, you can expect to save lots of time.

2. Saves Money

Mobile asphalt mixing plant saves money as it fails to consume a lot of energy. In reality, some mobile asphalt mixing plants saves energy. Manufacturers that will make these plants are usually planning to reduce energy consumption. So, you are going to never spend a lot of cash on energy.

There are many mobile asphalt mixing plants in the marketplace. Want to save money when buying a mobile asphalt mixing plant? Choose a reasonable plant. It is easy to discover it. Search for reputable manufacturers. compare their prices. And acquire an affordable one if you wish to spend less. Learn more information here: aimixasphaltplant.com

3. Long-lasting

Another benefit of choosing the right mobile asphalt mixing plant is that this plant lasts for a long time. You can easily understand how long a mobile asphalt mixing plant last. Talk with folks who suffer from used these plants. They will tell how much time they may have used their plant.